Application of Solidot IO-Link Bus I/O in Automotive Panel Welding Line Fixture Equipment

Automotive panel welding lines are a critical link in automobile manufacturing. Through the coordinated operation of multiple welding fixtures, they complete the positioning, clamping, and welding of body panel parts, ensuring the precision and strength of the body structure.

Solidot Products Used in This Case:

(IO-Link Master, PROFINET, 8-channel Class A interface, IP67)

(IO-Link Hub, 16-channel configurable input/output, PNP, IP67)

(IO-Link Hub, 16-channel digital input, PNP, IP67)

(IO-Link Hub, 16-channel digital output, PNP, IP67)

I. Production Process Introduction

The automotive panel welding line utilizes advanced welding processes. The specific workflow is: Workpiece Loading → Positioning & Clamping → Welding Execution → Status Monitoring → Workpiece Transfer.

[Workpiece Loading]: Industrial robots place the sheet metal parts onto the welding fixture, ensuring accurate workpiece positioning.

[Positioning & Clamping]: The fixture uses cylinders to drive locating pins and clamping arms to achieve precise fixation of the workpiece, preventing displacement during welding.

[Welding Execution]: Welding robots perform multi-point welding, ensuring welding strength and quality meet process requirements.

[Status Monitoring]: Monitor fixture status in real-time, including cylinder position, welding completion signals, etc., ensuring coordinated operation between all fixtures and robots.

[Workpiece Transfer]: After welding is completed, the fixture automatically releases, and the workpiece flows to the next station for subsequent processing.

II. I/O Module Application Method

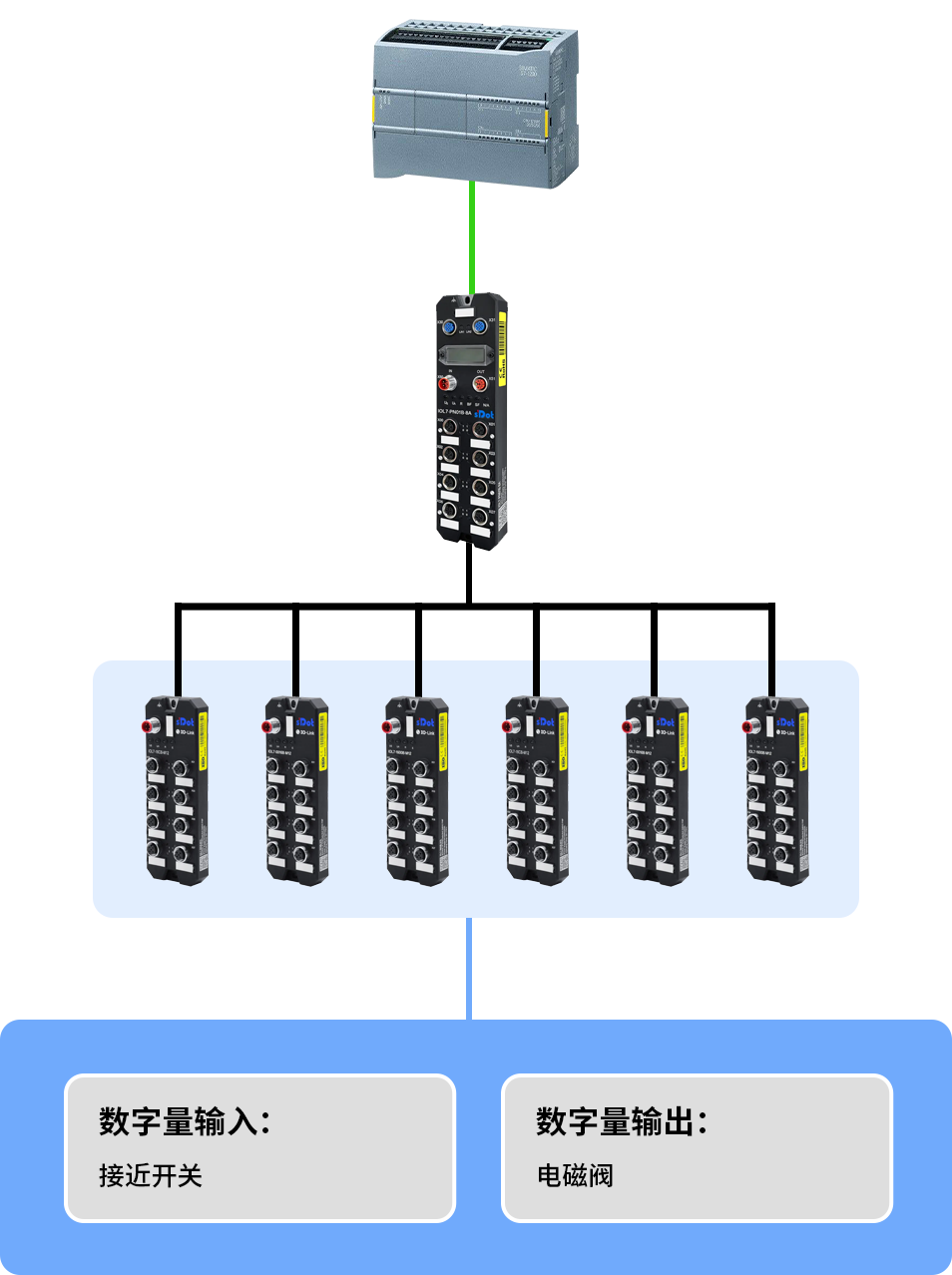

In this case, the welding line uses the PROFINET bus protocol. A Siemens S7-1200 PLC acts as the master controller, connecting via the bus network to multiple Solidot IO-Link bus I/O master modules (IOL7-PN01B-8A). Each master module is then connected to 6 slave modules (including IOL7-16CB-M12,IOL7-1600B-M12,IOL7-0016B-M12). One set of welding fixtures corresponds to one master station and its group of slave stations. One robot work station is configured with 4 sets of fixture units.

The master module (IOL7-PN01B-8A) enables data exchange between the PLC and the slaves, supporting remote parameter configuration and real-time status diagnosis. The various slave modules (IOL7-16CB-M12,IOL7-1600B-M12,IOL7-0016B-M12) are all used to connect proximity switches and cylinder solenoid valves, achieving signal acquisition and execution control: input modules acquire fixture status signals, and output modules drive cylinder actions, ensuring the welding process is synchronized and precise.

III. Solution Optimization Results

After adopting the Solidot IO-Link bus I/O solution, the system effectively optimized the wiring structure and maintenance mode while maintaining high performance. The connection between the master and slaves uses standard cables. Remote parameter configuration and real-time diagnostic functions improved commissioning and maintenance efficiency, while the system's anti-interference capability and stability were ensured.

IV. Solidot IO-Link Bus I/O

Solidot's IO-Link bus I/O modules can adapt to bus protocols such as EtherCAT and PROFINET. They feature plug-in (Slice-type) connectivity, diagnostic options, IP67 protection rating, shock resistance, and vibration resistance. Solidot IO-Link Bus I/O is widely used in industrial scenarios such as automotive manufacturing and logistics, enabling rapid device connection, efficient data transmission, and intelligent system management, thereby improving production efficiency.

Recommended Products

IOL7-PN01B-8A

PROFINET 8xClass-A Port IO-Link Master

IOL7-16CB-M12

IO-Link Hub that can be configured with a maximum of 16 channels for input or output, PNP

IOL7-1600B-M12

16 Channels Digital Input IO-Link Hub, PNP

IOL7-0016B-M12

16 Channels Digital Output IO-Link Hub, PNP