Solidot XB6 Series PROFINET Slice I/O Module in the non-standard automation industry

The client of this case is from the non-standard automation industry, and its business involves many fields such as semiconductor wafer and packaging and testing, micro assembly/electrical assembly/final assembly, automotive electronics/3C electronics, etc. This time, we will take "IGBT module dynamic and static test automation production line" and "side frame dispensing assembly equipment" as examples to introduce in detail the application of I/O modules of SOLIDOT Technology in assembly automation and test automation systems.

Application of SOLIDOT Technology Remote I/O in IGBT Module Dynamic and Static Test Automation Production Line

The production line consists of a loader, module dynamic testing equipment (including preheating system, automatic conveying system, cooling system, testing system), module static testing equipment (including independent insulation test, static test, 3D arch test and full-size test part), unloader, etc. It has high testing efficiency and is deeply integrated with the automated production line.

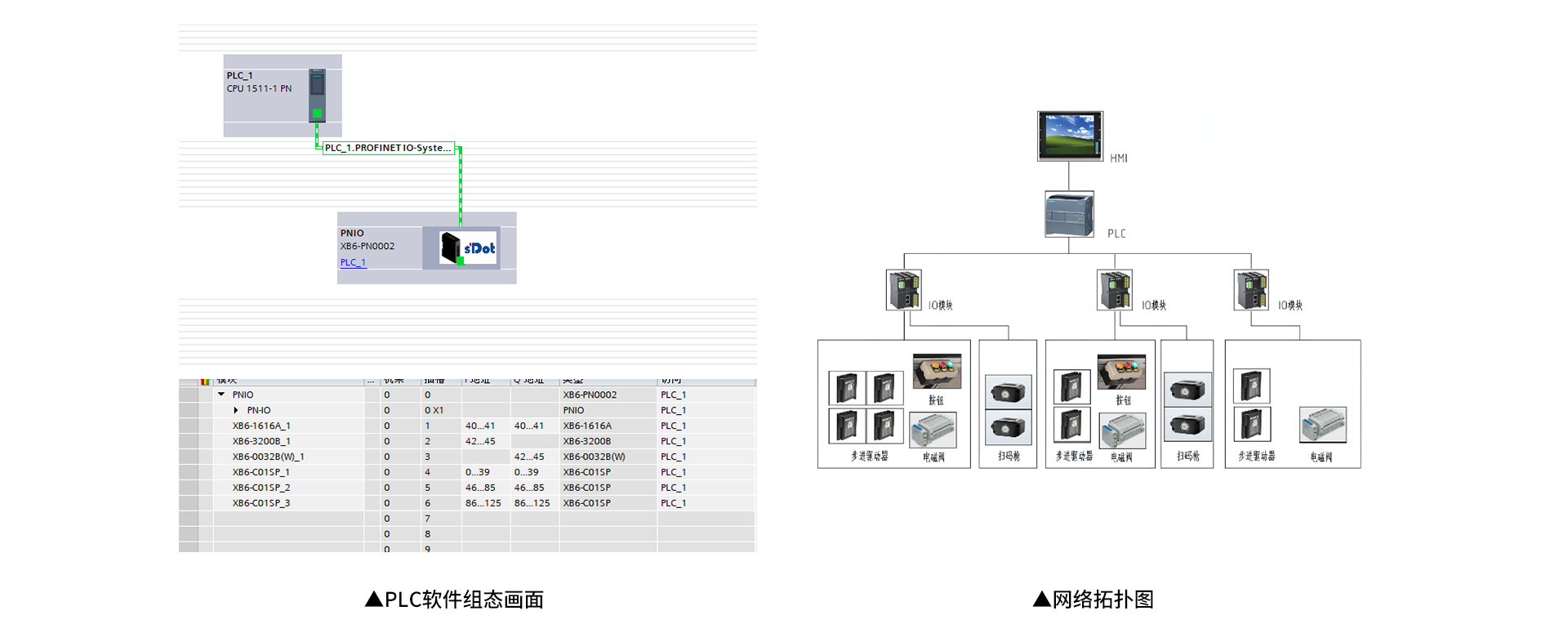

The whole system communicates through PROFINET protocol. Due to the large number of signal points and scattered locations, XB6 series plug-in I/O modules are used to solve the problem. Among them, the sensor detection signals during equipment operation are collected by XB6-3200A and XB6-3200B modules, the actuator signals, such as cylinders, are controlled by XB6-3200A and XB6-3200B modules, and XB6-1616A can simultaneously realize signal collection and signal output.

Application of SOLIDOT Technology Remote I/O in Side Frame Glue Dispensing Assembly Equipment

The equipment automatically takes the substrate and reads the QR code. Through recipe management, it has procedures such as laser marking, gluing, plasma cleaning, side frame installation, and screwing. After gluing different modules, the glue strips are visually inspected. After the substrate and side frame are assembled, the code is scanned to complete the information binding, and finally the equipment enters the downstream station curing furnace loading position to wait for loading.

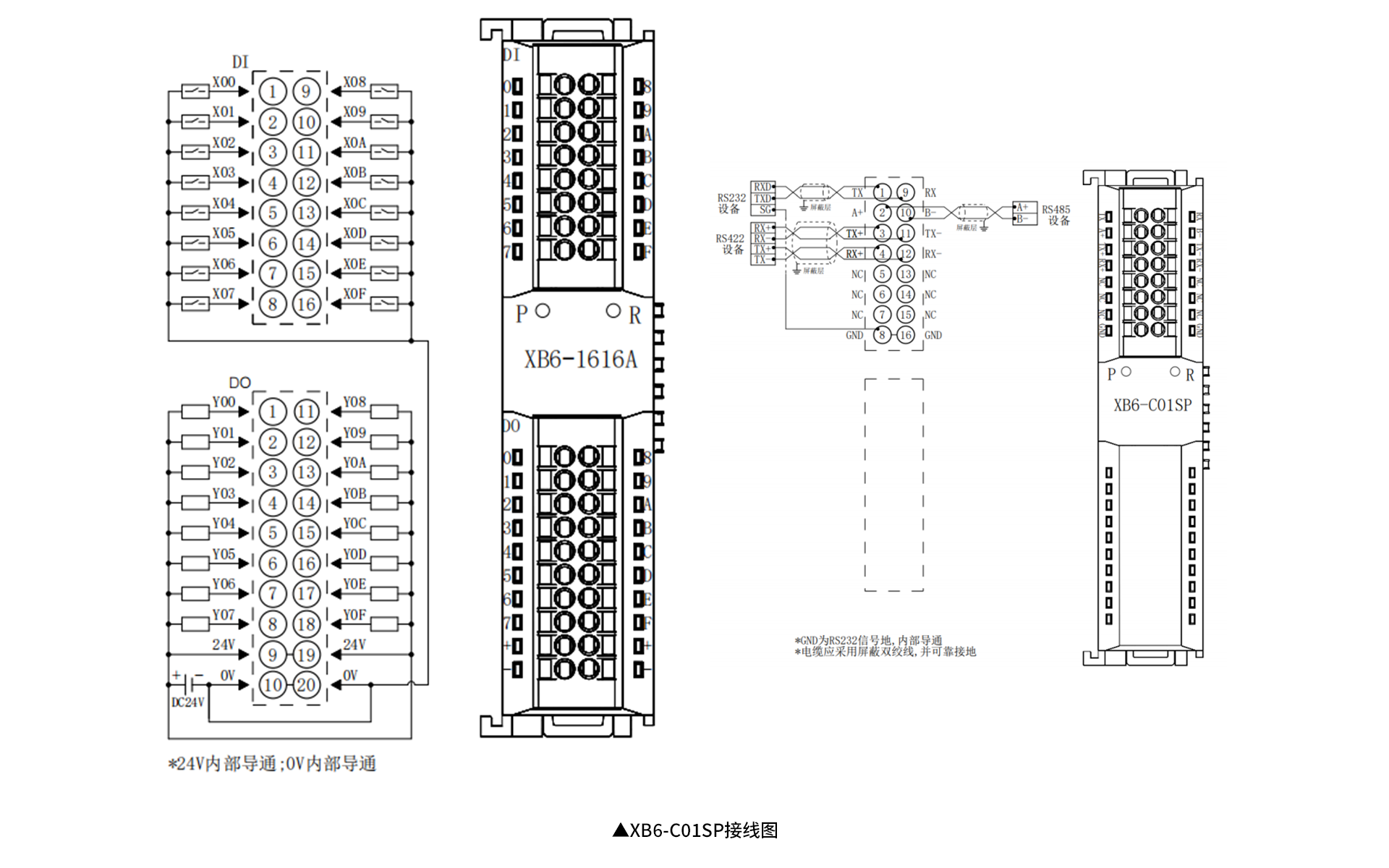

Since the system also requires a barcode scanner, the plug-in serial communication gateway module XB6-C01SP is used as an aid. Together with the XB6-PN0002 coupler, serial communication devices such as barcode scanners can be connected to the PROFINET bus system.

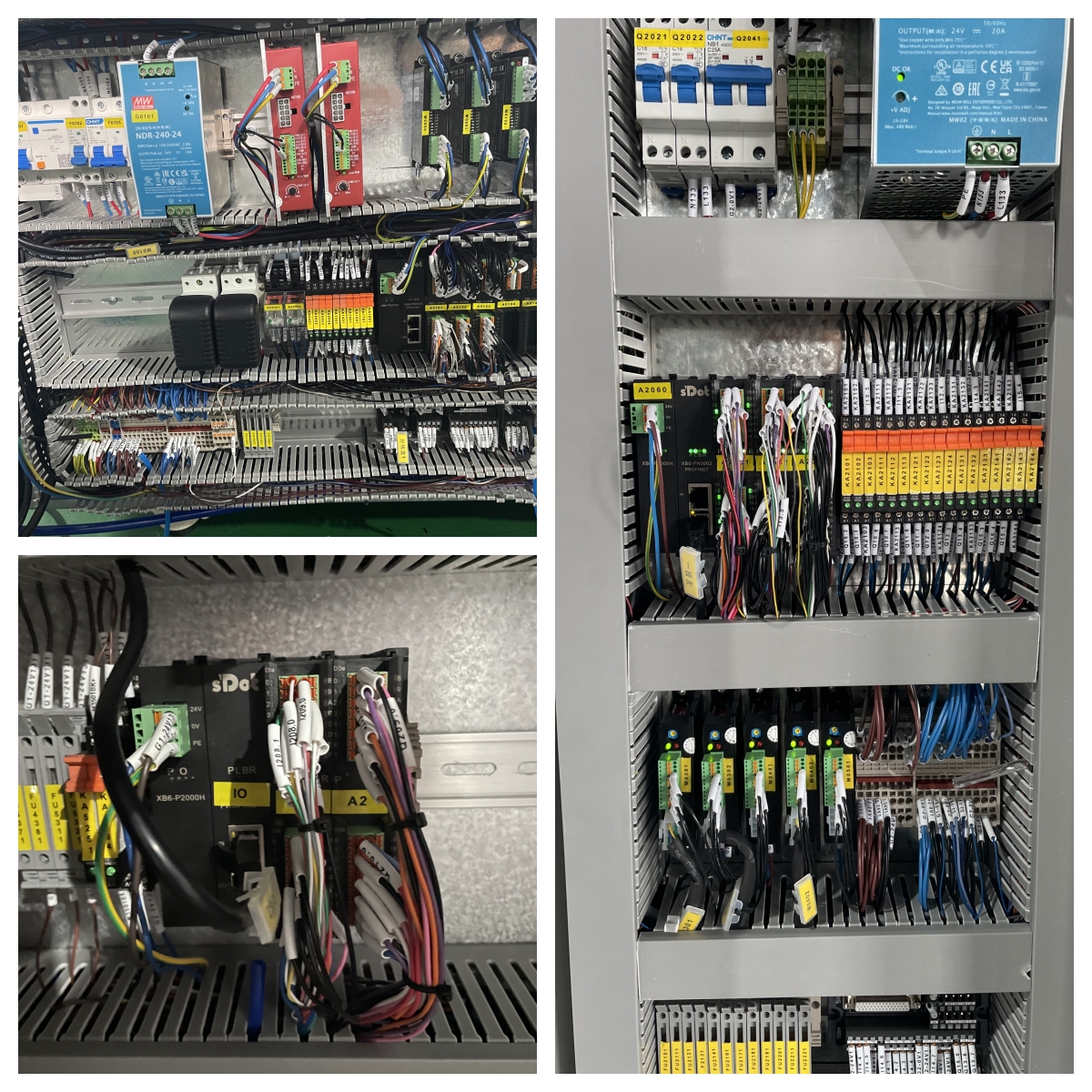

▲ Module cabinet installation diagram

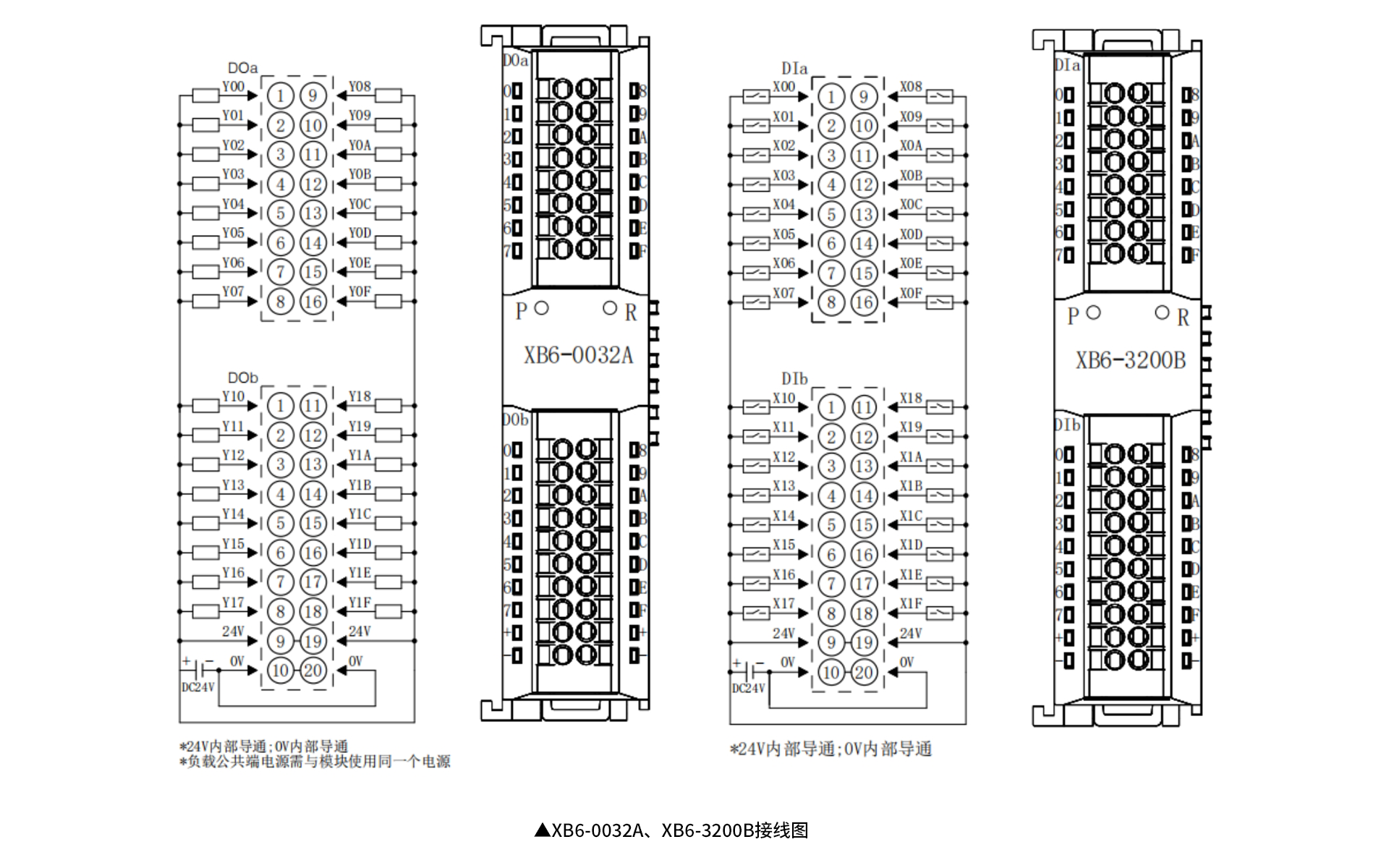

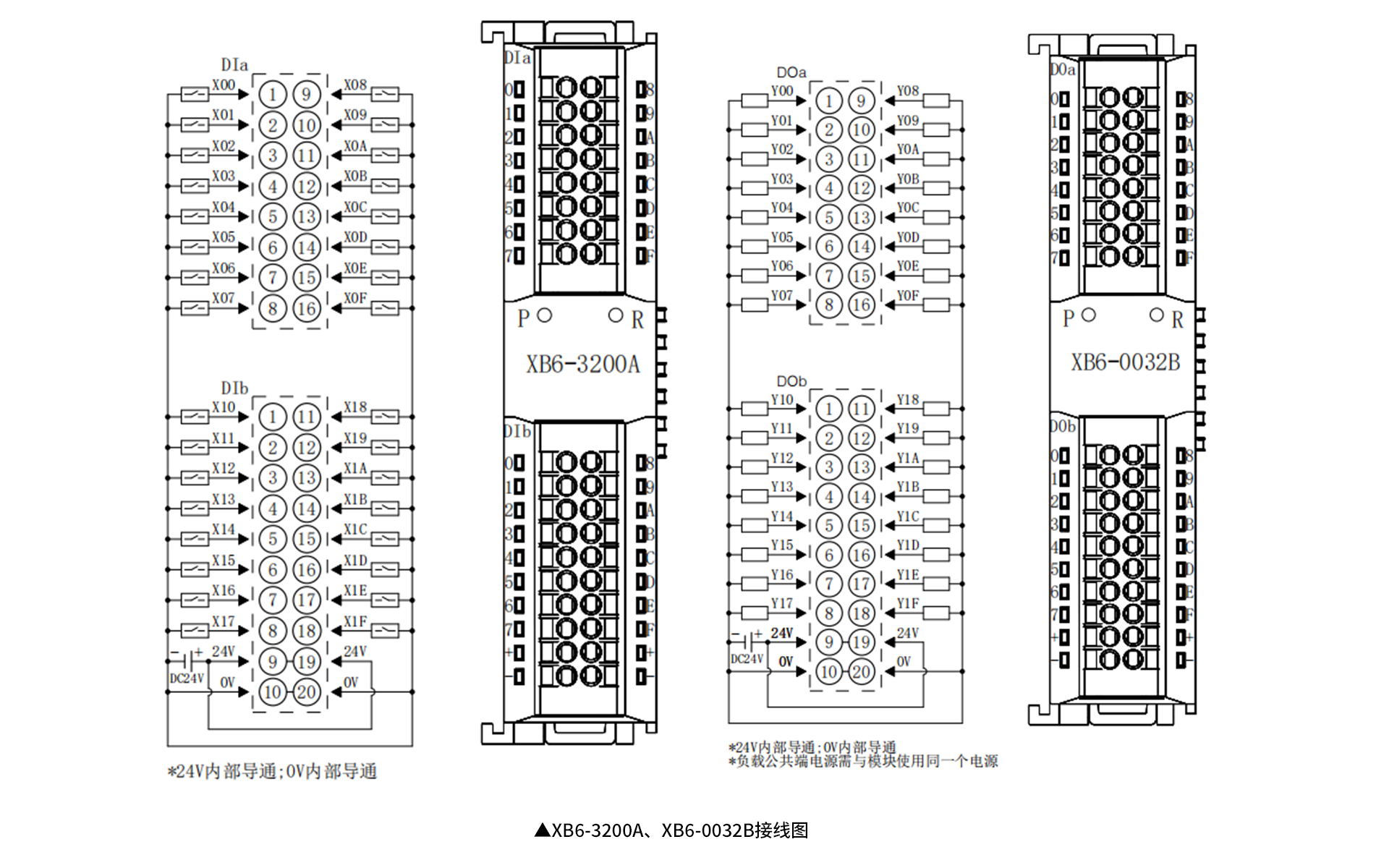

SOLIDOT Technology Remote I/O Wiring Diagram

Introduction to SOLIDOT Technology Remote I/O Products

XB6 series PROFINET protocol coupler is one of the classic products of SOLIDOT Technology. It is only 106*61*47mm in size and occupies a small space. With plug-in terminal blocks, it can be quickly wired and configured simply. It supports mainstream PROFINET master stations such as Siemens S7-1200, S7-1500, Codesys, etc., fully loaded with 32 slave stations, high-speed X-bus bus, maximum scan cycle 1ms, protection level IP20, stable operation and excellent performance.

In the above-mentioned assembly automation and test automation systems, the on-site solutions provided by SOLIDOT Technology perfectly meet the needs of decentralized device connection and large-scale signal acquisition. In conjunction with the XB6-C01SP gateway module, it very conveniently realizes the interconnection between serial devices and the PROFINET bus.

As a well-known domestic industrial bus solution provider, SOLIDOT Technology has an early layout in the field of domestic distributed I/O, rich experience, and strong R&D technology. It is precisely because of its high degree of professionalism that it can deeply understand customer needs and not only provide high-standard products in the industry, but also provide suitable exclusive solutions for customers from all walks of life with reliable performance and rich product lines.

Recommended Products

XB6-3200A

32 DI, NPN, European style terminal

XB6-0032A

32 DO, NPN, 0.5A, European style terminal

XB6-3200B

32 DI, PNP, European style terminal

XB6-0032B

32 DO,PNP,0.5A,European style terminal

XB6-PN2002ST

PROFINET Coupler kit (with power supply, end cover )

XB6-1616A

16 DI 16DO, NPN, 0.5A, European style terminal

XB6-C01SP

XB6 Series Serial Communication Modules