Application of Solidot XB6 series EtherCAT slice I/O module in photovoltaic velvet feeding and discharging equipment

The photovoltaic industry is a new energy industry encouraged by the state, and it is also a component of strategic emerging industries supported by the state. For the photovoltaic industry, the country has issued a number of industry-specific support policies to encourage the development of the photovoltaic industry while establishing and improving industry regulations, creating a good policy environment for the development of the photovoltaic industry.

The wet manufacturing process is the beginning of the solar cell production process. The original cell sheet obtained from the superior manufacturer or superior raw material factory will start its new career here, as the beginning of the life of the cell. Wet processes such as texturing, is one of the most difficult processes to control in the entire production process. The main function of the texturing machine is to remove the mechanical damage layer, increase the surface area of the cell, reduce the reflectivity of the cell surface, and clean the surface oil and impurities. This case will focus on the application of XB6 series EtherCAT protocol slice I/O modules of SOLIDOT Technology in photovoltaic texturing loading and unloading machine equipment.

Photovoltaic texturing loading and unloading machine equipment process description

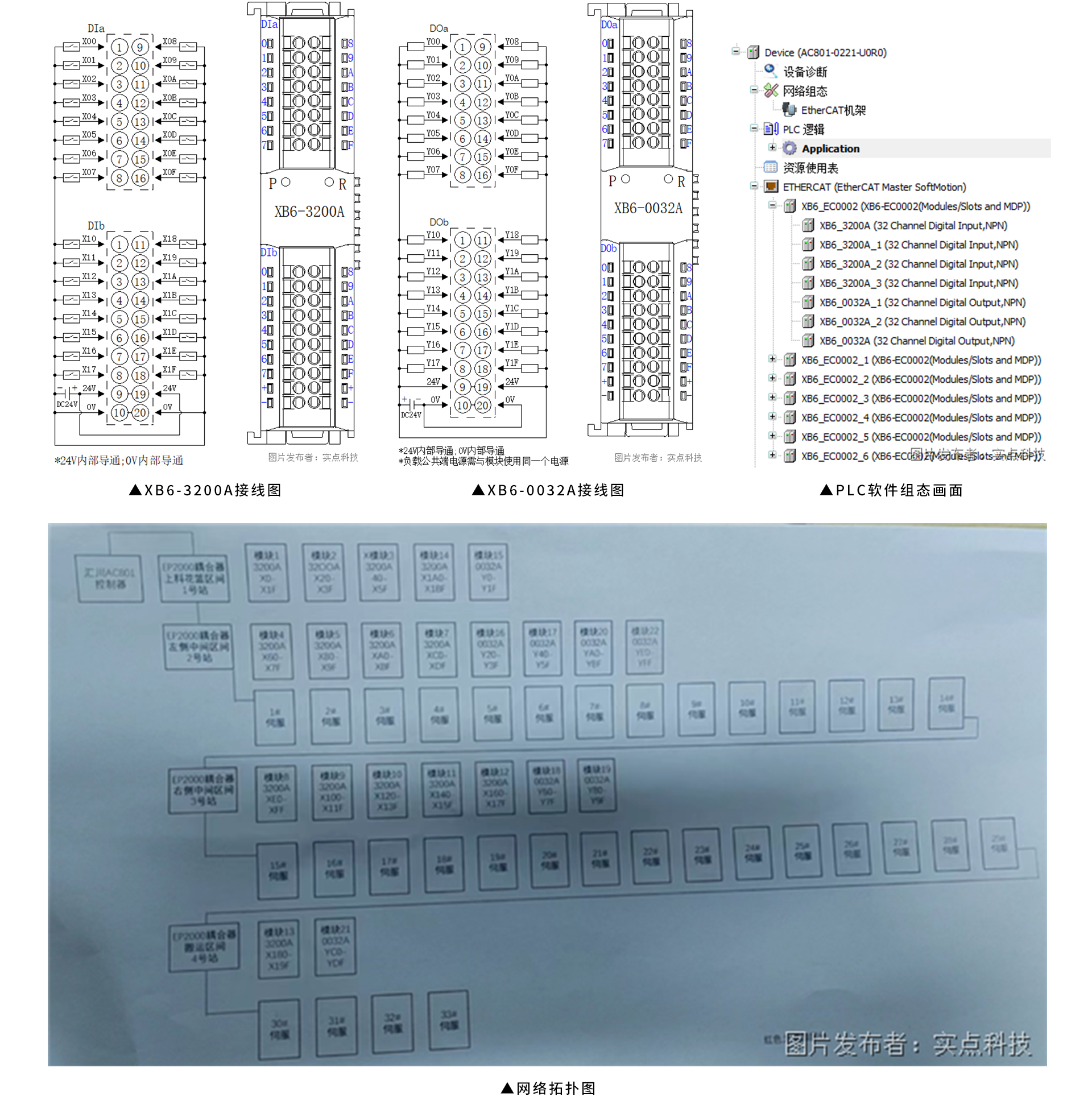

The raw materials are manually loaded into the designated position in the loading area, and then the AGV car automatically picks up the materials and transports them to the texturing loading machine. The loading machine transports the materials to the texturing machine for professional processing such as removing the mechanical damage layer. After the operation is completed, the materials is discharged through the texturing unloading machine and transported to the corresponding position by the AGV car. The main body of the loading and unloading machine is composed of conveyor belts, suction cups, flower baskets and other mechanisms. It has a large number of cylinders, photoelectric switches, proximity switches and other signals. It is characterized by a large number of signals and scattered installation locations. Therefore, the XB6 series slice I/O module is used to solve it. During the operation of the equipment, all sensor detection signals are collected by the XB6-3200A module, the actuator signals such as cylinders are controlled by the XB6-3200A module, and the servo motor controls the conveyor belt operation and transportation. The texturing loading machine uses 5 sets of XB6-EC series modules, and the texturing unloading machine uses 1 set of XB6-EC modules.

SOLIDOT I/O module PLC program configuration diagram

Module wiring diagram

SOLIDOT Remote I/O Product Introduction

In the application of the above-mentioned photovoltaic texturing loading and unloading machine, a large number of signals such as the photoelectric detection signal of the conveyor belt, the in-position signal of the cylinder, and the detection signal of the suction cup need to be collected. The large number of signals and the scattered installation positions have become difficulty. Using the XB6 series plug-ins of SOLIDOT Technology slice remote I/O not only solves the above problems, but the unique design of the product also brings the following advantages to on-site solutions:

*Small size, saving space in the control cabinet

*Simple configuration saves engineering design time

*Convenient installation and wiring, shortening assembly time

*Module model combinations are flexible to provide customers with flexible application solutions

*Can be expanded to a maximum of 32 I/O modules to adapt to various application scenarios

Independent research and development, professionalism. SOLIDOT Technology's I/O remote modules provide excellent solutions for customers from all fields with more reliable performance and abundant product lines.

Recommended Products

XB6-3200A

32 DI, NPN, European style terminal

XB6-0032A

32 DO, NPN, 0.5A, European style terminal

XB6-EC2002ST

EtherCAT coupler kit:inclue EtherCAT coupler(XB6-EC0002)、2A power supply(XB6-P2000H)、end cover( XB6-CVR00)