Application of Solidot's Slice Remote I/O Module XB6S in Automotive Waistline In-Line Punching/Cutting Equipment

Automotive waistline in-line punching/cutting equipment cuts continuous coiled materials to fixed lengths according to vehicle specifications. The material is fed to the inlet by a feeding mechanism, straightened by a flattening unit to eliminate deformation, and has its displacement signals monitored in real-time by a measuring wheel. When the set value is reached, the punching/cutting mechanism performs the cut.

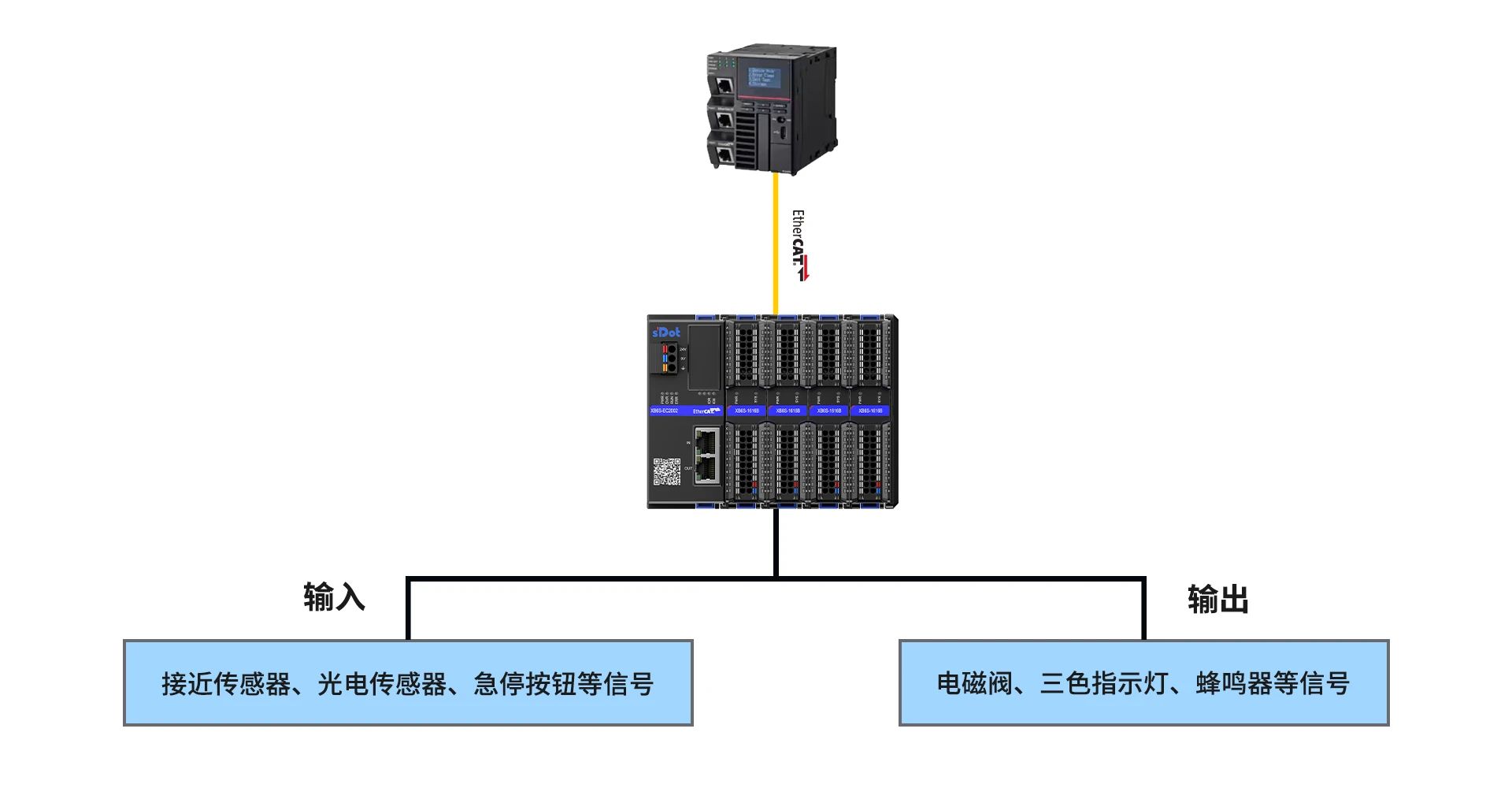

Solidot products used in this case: XB6S-EC2002, XB6S-1616B

I. Production Process Overview

Workflow: Material Loading → Straightening → Length Measurement → Punching/Cutting → Unloading

【Material Loading】

Feeding mechanism continuously transports raw material to the inlet station.

【Straightening】

Roller unit at inlet eliminates material curvature to ensure flatness.

【Length Measurement】

Measuring wheel collects displacement signals in real-time.

【Punching/Cutting】

Cutting mechanism triggers when target length is reached.

【Unloading】

Finished products are conveyed out while system automatically records data.

II. I/O Module Application

The system uses EtherCAT protocol with Keyence KV-X520 PLC as the control core. The coupler XB6S-EC2002 connects to the 16-channel DI/DO module XB6S-1616B.

XB6S-1616B functions:

Input channels: Collect signals from proximity sensors, photoelectric sensors, E-stop buttons.

Output channels: Control solenoid valves, 3-color indicator statuses, buzzers.

III. Solution Optimization Results

The client’s original I/O system relied on PLC expansion modules with high costs and limited channel flexibility. After adopting Solidot’s Slice Remote I/O Module XB6S series:

✔️ Reduced hardware costs

✔️ Maintained communication speed & reliability

IV. High-Reliability Slice Remote I/O Module XB6S Series

Solidot’s XB6S series supports multiple bus protocols and offers motion control, temperature acquisition modules. Features include:

⚡ Strict EMC testing | Ultra-strong anti-interference | Crash-free operation

⚡ Diagnostics | Alarms | Anomaly logging | Smart feedback

⚡ Tool-free installation

Recommended Products

XB6S-EC2002

EtherCAT filedbus coupler module(Flagship model)

XB6S-1616B

16-channel digital input and output module, Input NPN/PNP compatible, input filter default 3ms, output PNP type