Application of Solidot Remote I/O Module XB6S in Automotive Ultrasonic Plastic Welding Machines

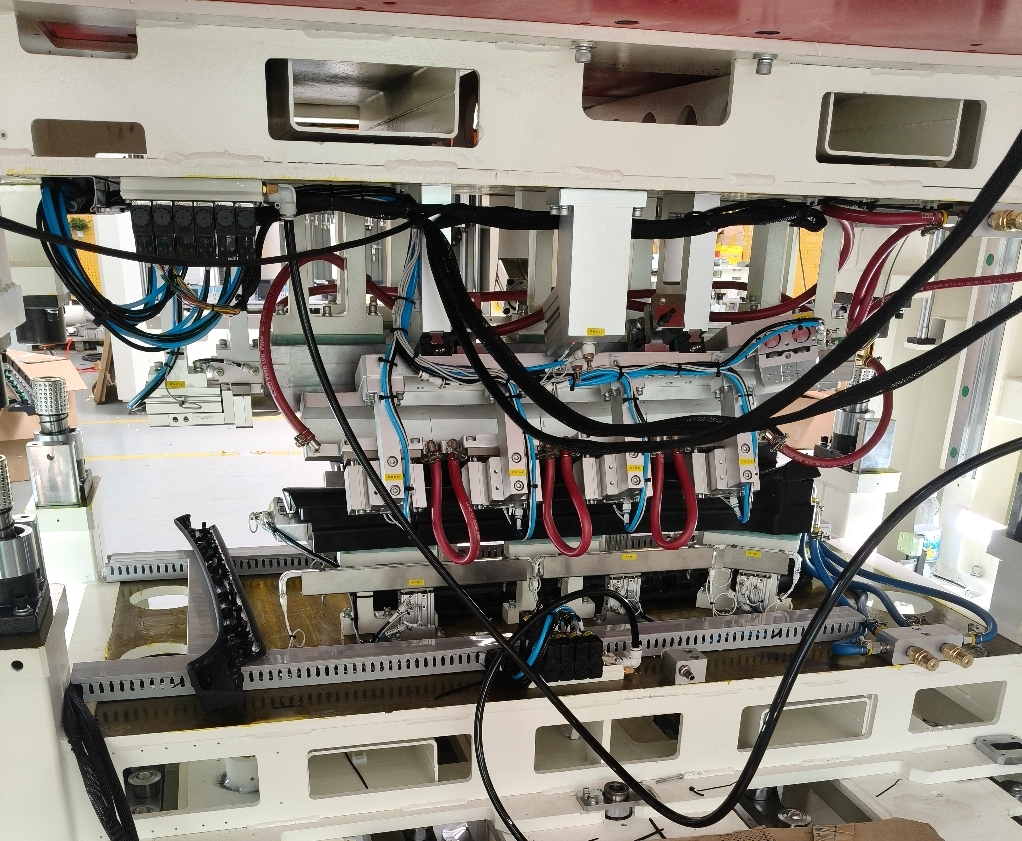

Ultrasonic plastic welding machines are key equipment in automotive parts production, widely used for joining and covering various plastic components. With increasing demands for vehicle lightweighting and interior quality, these machines require high-precision control, coordinated motion, real-time status monitoring, and safety interlocking, placing high demands on the stability of remote I/O signal transmission.

Products used in this case study:

【For automotive underbody shield welding process】

XB6S-3200, XB6S-0032B, XB6S-A40V

【For automotive armrest covering process】

XB6S-3200, XB6S-0032B, XB6S-A08I

I. Production Process Introduction

This equipment is used for both automotive underbody shield welding and armrest covering processes, detailed below:

【Underbody Shield Welding Process】

Pretreatment → Positioning & Clamping → Ultrasonic Emission → Mold Melting & Fusion → Pressurization & Curing

【Pretreatment】

Clean and align the plastic parts to be welded, ensuring the welding surface is flat and free of impurities.

【Positioning & Clamping】

Use pneumatic clamps to precisely secure the workpiece, preventing displacement during welding.

【Ultrasonic Emission】

Activate the ultrasonic generator to transmit high-frequency vibrations to the welding surface, generating localized heat.

【Mold Melting & Fusion】

Under combined pressure and ultrasound, the material surfaces melt and interpenetrate, achieving material bonding.

【Pressurization & Curing】

Maintain pressure until the weld seam cools and sets, ensuring structural strength.

【Armrest Covering Process】

Cutting → Glue Spraying → Preheating → Positioning → Mold Press Covering → Trimming

【Cutting】

Precisely cut the surface material according to size requirements for covering preparation.

【Glue Spraying】

Control adhesive amount via a proportional valve, spraying evenly onto the substrate surface.

【Preheating】

Gently heat the material to improve flexibility and activate the adhesive layer.

【Positioning】

Precisely align the surface material with the frame to avoid wrinkles or misalignment after covering.

【Mold Press Covering】

Apply pressure through molds to make the surface material tightly adhere to the frame contour, ensuring a smooth appearance without bubbles.

【Trimming】

Trim excess material to complete the final cover.

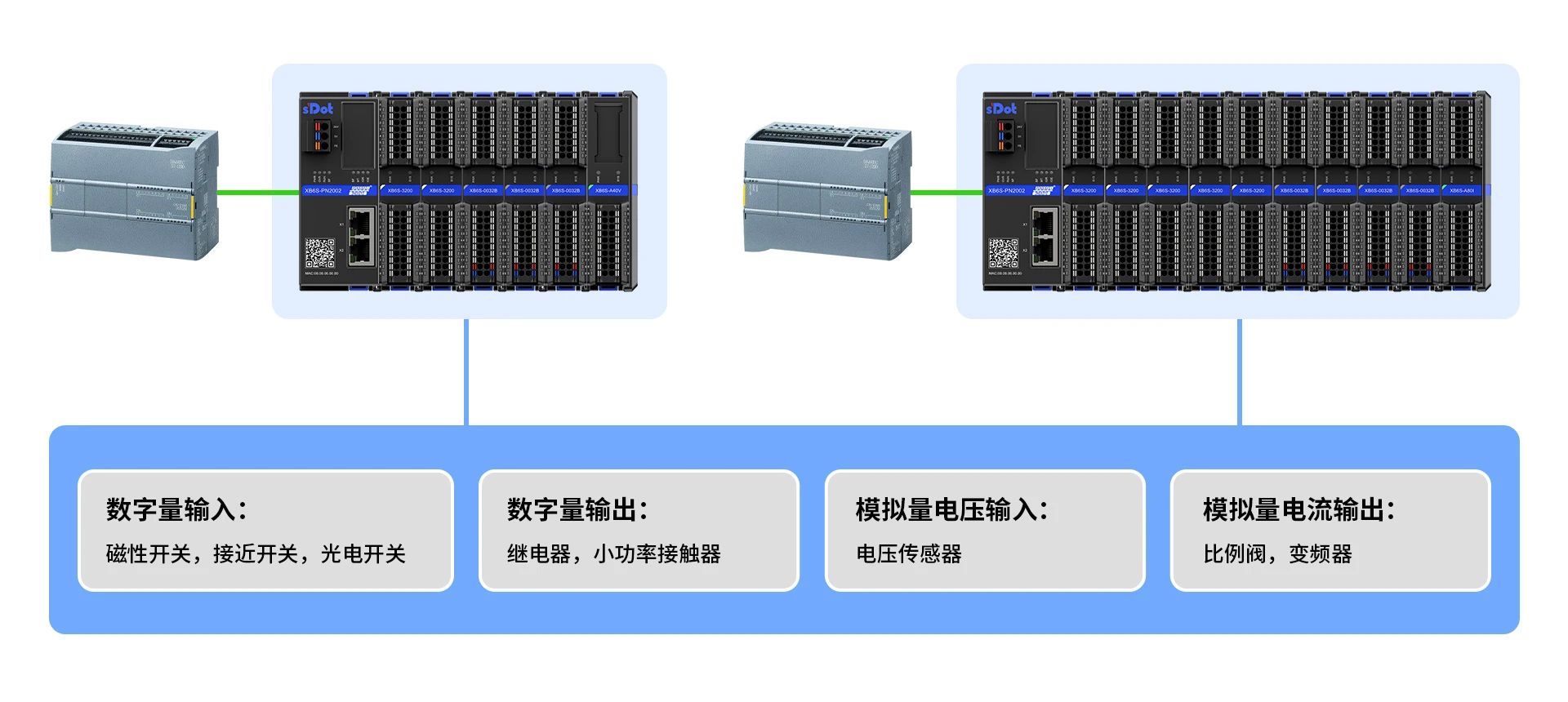

II. I/O Module Application Method

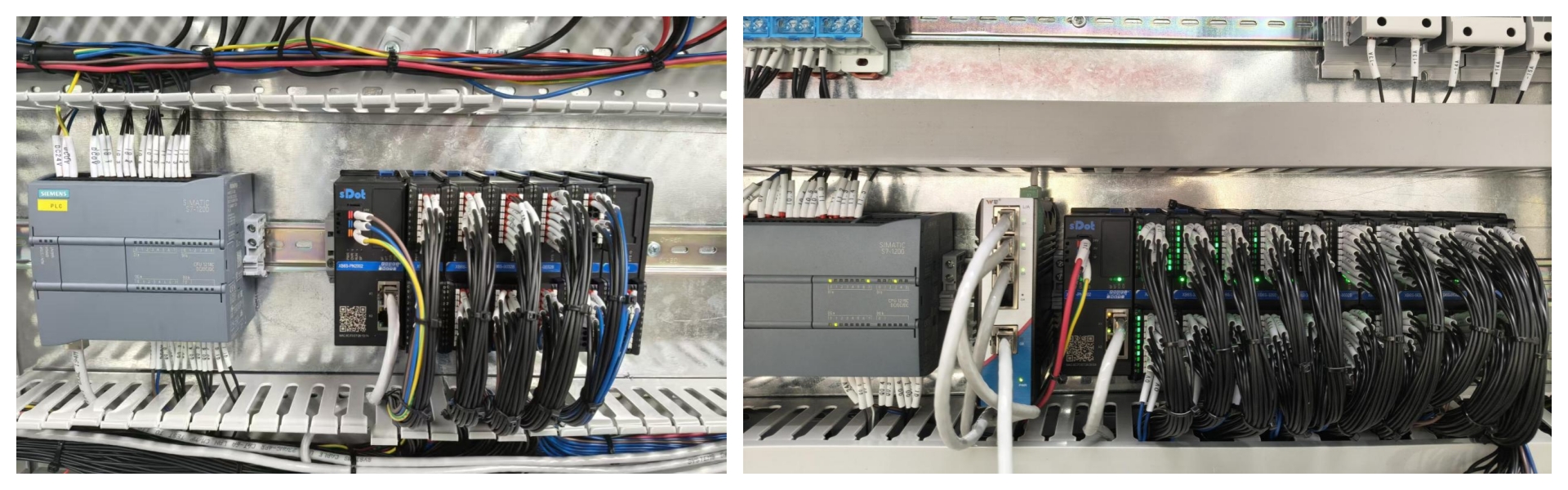

The equipment uses the PROFINET bus protocol. A Siemens S7-1200 series PLC acts as the master station, connecting various I/O modules via the Solidot remote I/O XB6S PROFINET protocol coupler XB6S-PN2002 to build a highly reliable communication network. The PLC handles process logic and motion control command scheduling, while the remote I/O modules handle field signal acquisition and output execution.

The digital input module XB6S-3200 collects detection signals from magnetic switches, proximity switches, photoelectric sensors, and safety interlock statuses at various stations in real-time. The digital output module XB6S-0032B, with a load capacity of 0.5A per channel, can directly drive relays and low-power contactors. The analog current output module XB6S-A08I, with high precision and resolution, enables precise control of proportional valves and frequency converters. The analog voltage input module XB6S-A40V collects signals from voltage sensors for controlling welding depth.

III. Solution Optimization Results

After adopting the XB6S series products, the customer's remote I/O system showed significant improvements in anti-interference, convenience, and scalability. The XB6S offers excellent overall EMC performance and superior noise immunity, ensuring stable signal transmission. It features diagnostic, alarm, and exception logging functions, facilitating easier equipment maintenance. The high precision of the analog modules effectively improves control accuracy for devices like frequency converters and proportional valves. The digital output module's load capacity of 0.5A per channel and 16A total for 32 channels allows direct driving of relays and low-power contactors.

IV. Highly Reliable Remote I/O Module XB6S Series

The Solidot remote I/O module XB6S series adapts to various bus protocols and includes functional modules for motion control and temperature acquisition. The products undergo rigorous EMC testing, offer superior noise immunity, and reject disconnections. They support diagnostics, alarms, and exception logging for intelligent feedback and ease of use.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032B

32-channel digital output module, output PNP type

XB6S-A40V

4-channel analog voltage input module, Single-ended signaling, adjustable range: Disable, -10V~+10V, 0V~10V, -5V~+5V, 0V~5V, and 1V~5V

XB6S-A08I

8-channel analog current output module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA