Application of Solidot's Integrated Remote I/O Modules in Fully Automated Lithium Battery Drying Lines

The fully automated lithium battery drying line is a core process in power battery production. It controls battery moisture content through vacuum baking to ensure cell performance and safety. This line integrates multiple automated processes including barcode scanning, robotic arm loading/unloading, transfer, vacuum baking, and quality inspection, enabling continuous and efficient processing from cell feeding to baking completion.

I. Production Process Overview

Workflow:

Battery Scanning

Barcode scanners automatically read cell codes before entering the drying line, providing data for process parameter matching and quality traceability.

Battery Loading

Robotic arms grasp batteries and secure them in dedicated fixtures with built-in positioning sensors, ensuring precise alignment with baking chambers to prevent uneven heating.

Fixture Transfer

Fixtures are moved to vacuum baking chambers, with real-time monitoring of position signals and limit feedback to avoid collisions or deviations.

Vacuum Baking

After vacuumization, high-temperature baking initiates. The system dynamically adjusts heating power and vacuum valve openings by synchronously collecting temperature, pressure, and time data, ensuring moisture removal efficiency and process consistency.

Battery Unloading

Post-baking, robotic arms unload batteries for quality checks, and fixtures return to initial stations for reuse.

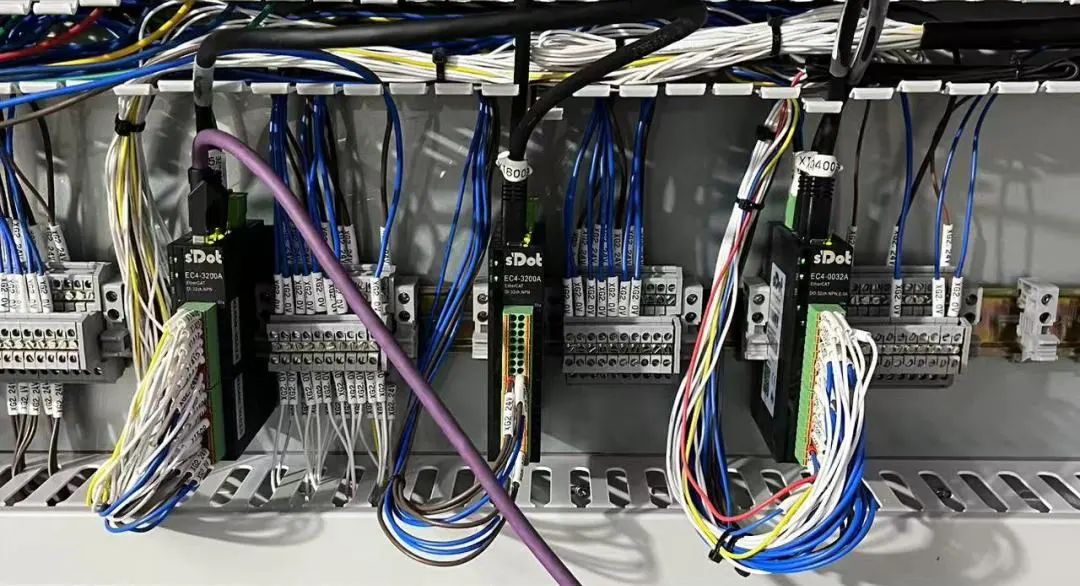

II. I/O Module Implementation

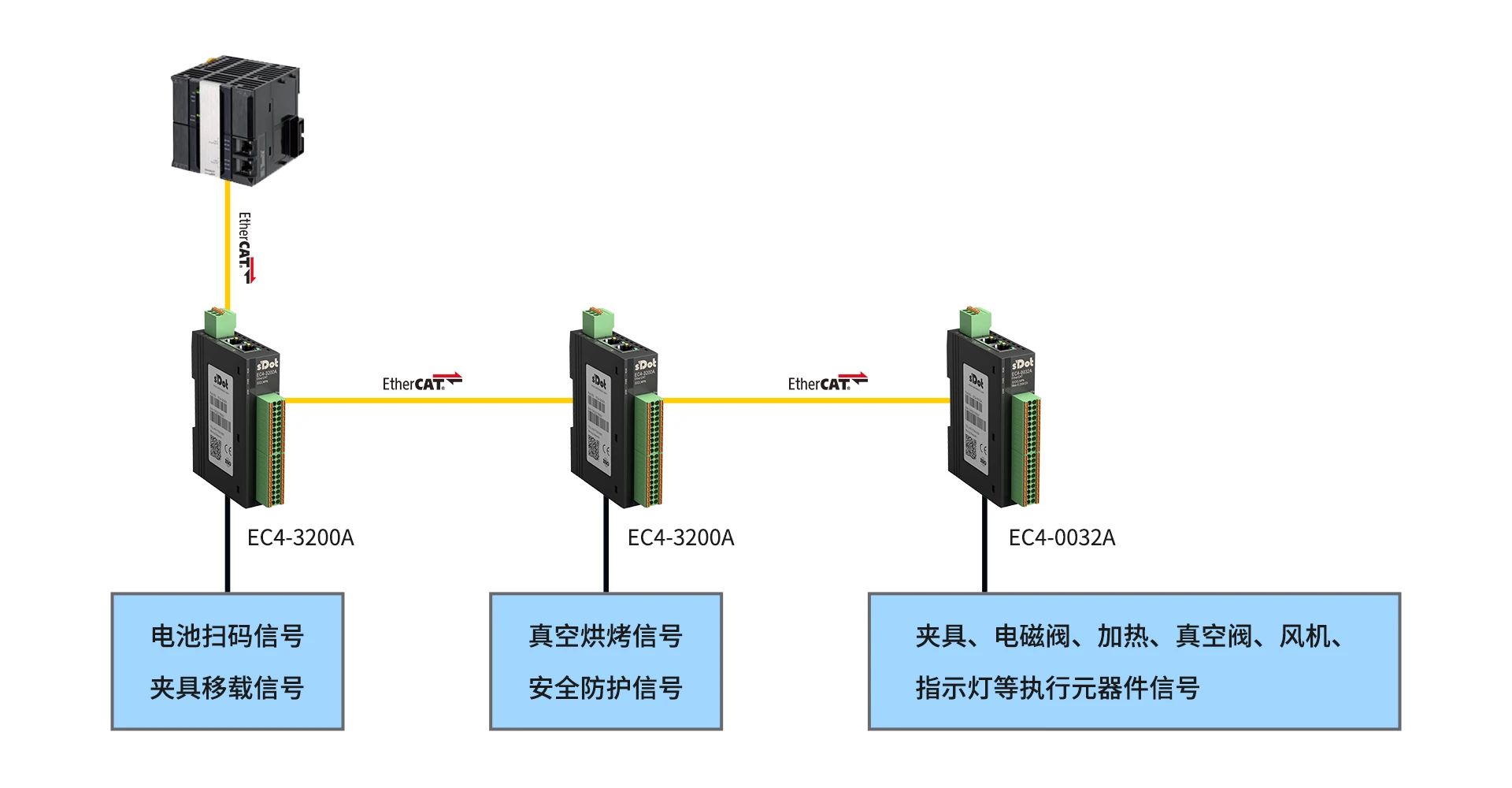

The line uses EtherCAT bus protocol with Omron NJ-series PLCs, integrated with Solidot's EC4-3200A (32-point digital input) and EC4-0032A (32-point digital output) modules. Single modules cover multi-station needs:

EC4-3200A Inputs:

Trigger signals, scan completion feedback

Fixture positioning and transfer mechanism limits

Vacuum pump status, chamber door switches, overtemperature alarms

Emergency stops and safety light curtains

EC4-0032A Outputs:

Fixture clamping, solenoid valve releases, heating element control

Vacuum valve operation, fan activation, indicator lights

III. Reference Topology

PLC: Omron NJ-series

Application: Fully Automated Lithium Battery Drying Line

IV. Optimization Results

Solidot's integrated remote I/O modules (EC4-3200A/EC4-0032A) meet distributed I/O demands with compact size and high-speed communication. They simplify wiring, reduce maintenance costs, and deliver high reliability for scaled production.