Application of Solidot Remote I/O Module XB6S in Aluminum Shell Motor Valve Threading and Soldering Equipment

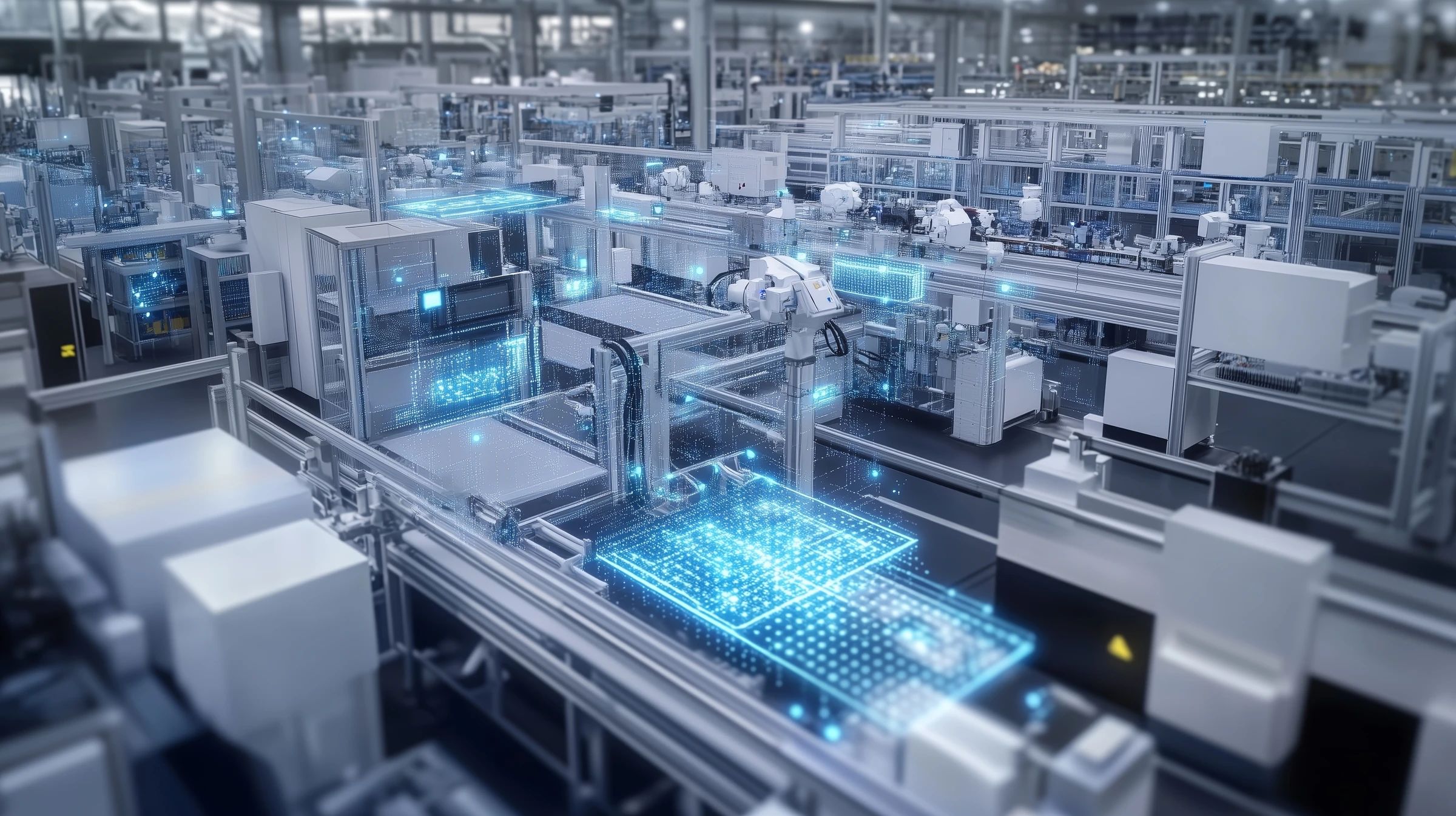

The aluminum shell motor valve threading and soldering equipment requires completion of processes including workpiece positioning, wire threading, solder curing, and quality inspection. To meet demands for high efficiency, stable soldering, and precise workpiece positioning, the equipment must coordinate multi-axis motion, respond to sensor signals in real time, and control actuators. Adopting Solidot's remote I/O module XB6S series effectively simplifies wiring, enhances communication anti-interference capability, and ensures production stability.

Solidot Products Used in This Case:

I. Production Process Overview

Automated threading and soldering workflow: Workpiece positioning → Wire threading → Soldering machine → Quality inspection/unloading

【Workpiece Positioning】

The conveyor transports workpieces to designated stations; after detection confirms positioning, clamping mechanisms secure them.

【Wire Threading】

The threading mechanism activates, precisely inserting wires into specified positions on workpieces.

【Soldering Machine】

Automatic soldering is performed according to process requirements.

【Quality Inspection/Unloading】

Conductivity and appearance inspections are conducted; qualified products are removed by the conveyor while production data is recorded.

II. I/O Module Application

The system utilizes PROFINET bus protocol with Siemens S7-1500 PLC as the control core. I/O modules (including digital input module XB6S-3200, digital output module XB6S-0032A, and 4-channel PTO pulse output module XB6S-PT04A) are connected via coupler XB6S-PN2002.

The PLC issues commands and collects data uniformly through XB6S-PN2002:

Pulse output module XB6S-PT04A directly outputs pulse sequences to control stepper/servo motors for positioning and feeding.

Digital input module XB6S-3200 collects product-in-position signals, limit switches, and button status in real time.

Digital output module XB6S-0032A controls conveyor start/stop, gripper cylinder actions, soldering station activation, and status indicators.

III. Solution Optimization Results

The customer’s original solution relied on PLC bus servo drives for positioning, incurring high costs and limited scalability.

After adopting Solidot’s remote I/O XB6S series:

XB6S-PT04A provides pulse control, reducing hardware costs.

XB6S modules offer superior anti-interference, enhancing production efficiency and stability.

IV. High-Reliability Remote I/O Module XB6S Series

Solidot’s XB6S remote I/O series supports multiple bus protocols and includes motion control/temperature acquisition modules. Key features:

Rigorous EMC testing ensures ultra-strong anti-interference and zero disconnections.

Diagnostics, alarms, and anomaly logs enable smart feedback and user-friendly operation.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032A

32-channel digital output module, output NPN type

XB6S-PT04A

4-channel PTO pulse output module