Solidot Remote I/O Module XB6S Application in Dishwasher Production Lines

As a common household appliance, the production of dishwashers involves multiple precision processes such as sheet metal processing, component assembly, functional testing, and packaging. The entire line requires efficient coordination of various mechanical and sensor actions like conveying, positioning, gripping, and detection, placing high demands on the control system's real-time response, signal stability, and anti-interference capability. The Solidot Remote I/O Module XB6S series, utilizing the PROFINET bus, provides a highly integrated and reliable signal transmission solution for dishwasher production lines, significantly enhancing equipment automation levels and production consistency.

Products used in this case study:

I. Production Process Introduction

The dishwasher production line primarily includes the following steps:

Sheet Metal Loading → Conveying & Positioning → Gripping & Transfer → Assembly & Welding → Leak Testing → Functional Testing → Packaging & Offline

Sheet Metal Loading: Sheet metal parts are automatically conveyed via a belt to the processing station for continuous feeding.

Positioning & Clamping: A gripper mechanism grabs and precisely positions the sheet metal, while pneumatic clamps securely hold it in preparation for welding.

Welding & Forming: Robotic welding guns or automatic welders complete the sheet metal welding along predefined paths, ensuring structural strength and sealing.

Leak Detection: Compressed air or test fluid is introduced, and pressure sensors determine the machine's sealing performance to eliminate leakage defects.

Functional Testing: Actual usage conditions are simulated to test dishwasher functions such as water intake, drainage, heating, and electrical circuits.

Packaging & Offline: Qualified products are conveyed to the packaging area via a belt, where they are packaged by robots or manually before being taken offline and sent to storage.

II. I/O Module Application Method

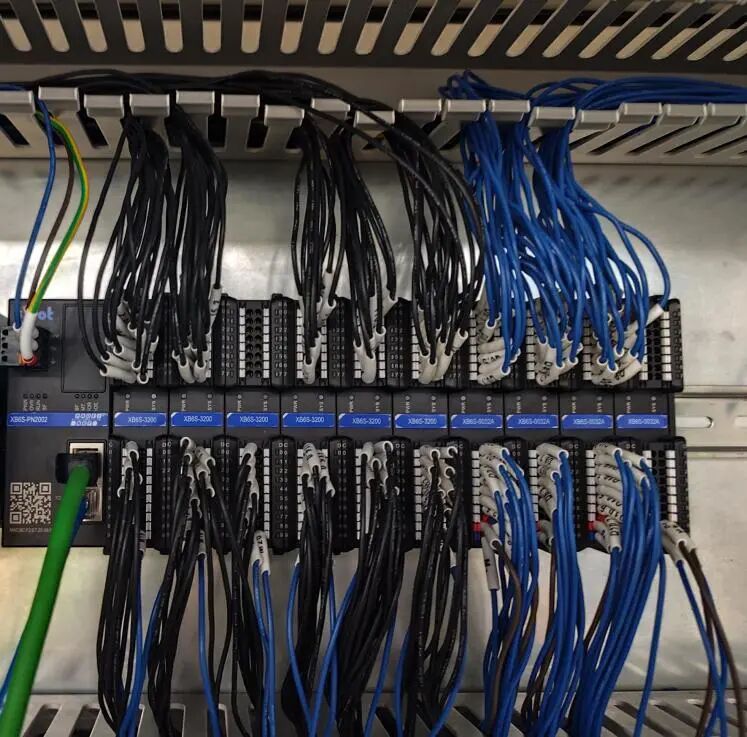

The system employs the PROFINET bus protocol, with a Siemens S7-1500 PLC as the master station, connected to remote I/O modules via the coupler XB6S-PN2002 to form a real-time control network. The PLC handles overall line logic scheduling, motion control, and process management, while the remote I/O modules are responsible for collecting various field signals and outputting execution commands, working together to achieve high-precision and high-response control.

The Digital Input Module XB6S-3200 collects signals from photoelectric sensors, proximity switches, and magnetic switches at various stations: detecting material arrival during loading, providing gripper position status during positioning and clamping, and monitoring clamp sealing status during leak detection. This provides the PLC with accurate status judgment and safety interlock guarantees.

The Digital Output Module XB6S-0032A, with its 0.5A load capacity per channel, directly drives solenoid valves, relays, and indicator lights. It controls conveyor start/stop, gripper cylinder actuation, welding start/stop, and audible/visual alarms, ensuring that actuators at each stage operate accurately according to the process sequence, thereby improving overall line response speed and reliability.

III. Solution Optimization Results

Compared to the customer's original solution, the XB6S series significantly simplifies the wiring architecture through modular integration. While ensuring efficient and stable system operation, it effectively reduces comprehensive operation and maintenance costs. Particularly noteworthy is the scheme's ability, leveraging multi-module coordination and superior anti-interference design, to handle complex industrial environments with multiple interference sources like motors and welding equipment. It effectively solves interference problems during signal transmission, ensures long-term, stable, and reliable system operation, and greatly enhances production line continuity and efficiency.

IV. High-Reliability Remote I/O Module XB6S Series

The Solidot Remote I/O Module XB6S series is compatible with various bus protocols and includes functional modules for motion control and temperature acquisition. The products undergo rigorous EMC testing, feature superior noise immunity, and resist disconnections. They support diagnostics, alarms, and anomaly log recording, enabling intelligent feedback and ease of use.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032A

32-channel digital output module, output NPN type