Solidot Remote I/O Module XB6S in Large-Sized Bonding Equipment Applications

Large-sized bonding equipment is a core asset in precision electronics manufacturing, responsible for mounting various components onto substrates. As panel sizes increase and yield requirements rise, these machines demand high positioning accuracy, multi-axis coordinated motion, and real-time process monitoring, placing stringent requirements on the communication real-time performance and stability of control systems. Implementing Solidot's Remote I/O Module XB6S series significantly reduces wiring complexity and ensures high-speed production.

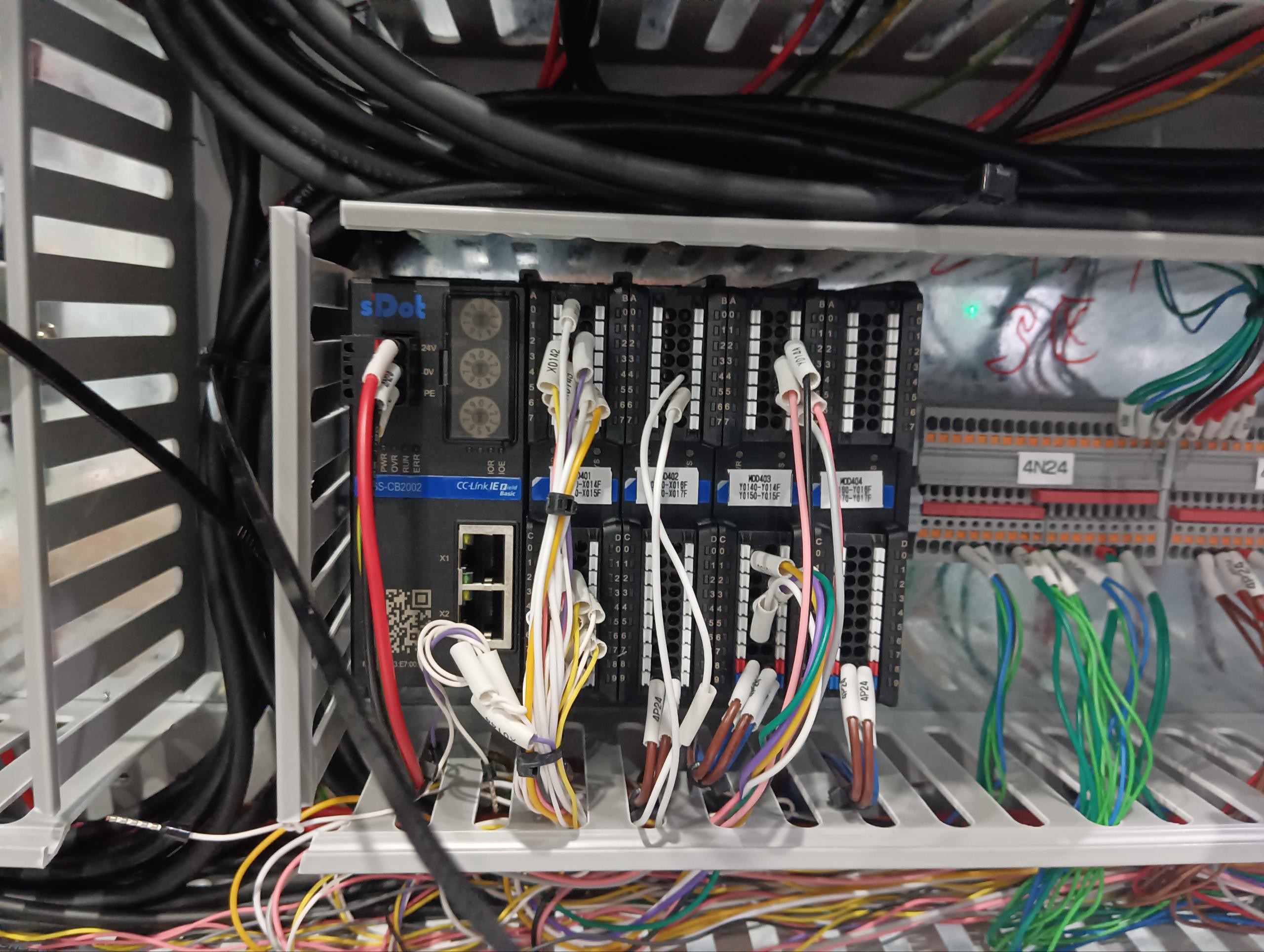

Solidot Products Used in This Case:

XB6S-CB2002, XB6S-3200, XB6S-0032A, XB6S-PT04A

I. Production Process Overview

Intelligent Bonding Workflow: Substrate Positioning → Bonding Execution → Pressure Control → Defect Detection

Substrate Positioning: Set bonding coordinates and pressure parameters; vision systems assist transfer mechanisms in precisely positioning substrates.

Bonding Execution: Monitor bonding head position, motor speed, and pressure curve in real-time; perform closed-loop dynamic trajectory adjustments to prevent misalignment or component damage.

Pressure Control: Precisely regulate bonding force and temperature to ensure uniform conductive adhesive curing, preventing cold soldering or substrate damage.

Defect Detection: Identify flaws like weak/no bonds; trigger real-time alarms/reject defective products; log data for process optimization.

II. I/O Module Implementation

The system uses CC-Link IE Field Basic protocol. Solidot modules – digital input XB6S-3200, digital output XB6S-0032A, and 4-channel PTO pulse outputXB6S-PT04A– connect via coupler XB6S-CB2002 to Mitsubishi R32ENCPU PLCs.

XB6S-3200 collects critical signals: substrate presence sensors, safety door locks, and air pressure threshold alarms.

XB6S-0032A controls conveyor motors, vacuum valves, clamping cylinders, alarm lights, and cooling systems.

XB6S-PT04A executes PLC trajectory commands, outputting pulses to servo drives for high-precision X/Y/Z linear motion and rotational positioning of bonding heads.

These modules jointly ensure positional accuracy, closed-loop force control, and multi-axis synchronization for consistent large-panel bonding quality.

III. Solution Comparison

The legacy solution (relays + standard I/O) had critical flaws: pulse signal interference caused positioning drift during multi-axis motion; complex long-distance wiring increased troubleshooting time and limited scalability.

After adopting Solidot’s XB6S Remote I/O:

Field wiring complexity reduced

Pulse signal transmission stabilized

Multi-axis positioning accuracy enhanced

Pressure closed-loop response and synchronization improved

Partial replacement of dedicated motion controllers lowered hardware costs.

IV. High-Reliability Remote I/O Module XB6S Series

Solidot's XB6S series supports multiple fieldbus protocols and integrates motion control/temperature acquisition modules. Certified by rigorous EMC tests, it delivers exceptional noise immunity and connection stability. Features include diagnostics, alarms, anomaly logging, and smart feedback for ease of use.

Recommended Products

XB6S-CB2002

CC-Link IE Field Basic filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032A

32-channel digital output module, output NPN type

XB6S-PT04A

4-channel PTO pulse output module