Application of Solidot Slice Remote I/O Module XB6S in Aluminum Drawing Machines

The aluminum drawing machine is a critical equipment in aluminum processing, responsible for uniformly pulling aluminum profiles from extruders to ensure dimensional accuracy and surface quality. With increasing industry demands for automation and intelligence, these machines require precise speed control, tension adjustment, and multi-device coordination during operation, placing higher demands on the real-time performance and stability of control systems. By implementing remote I/O technology, aluminum drawing machines achieve seamless signal acquisition, equipment synchronization, and process parameter optimization, helping enterprises enhance production efficiency and product quality to meet the high standards of modern aluminum processing.

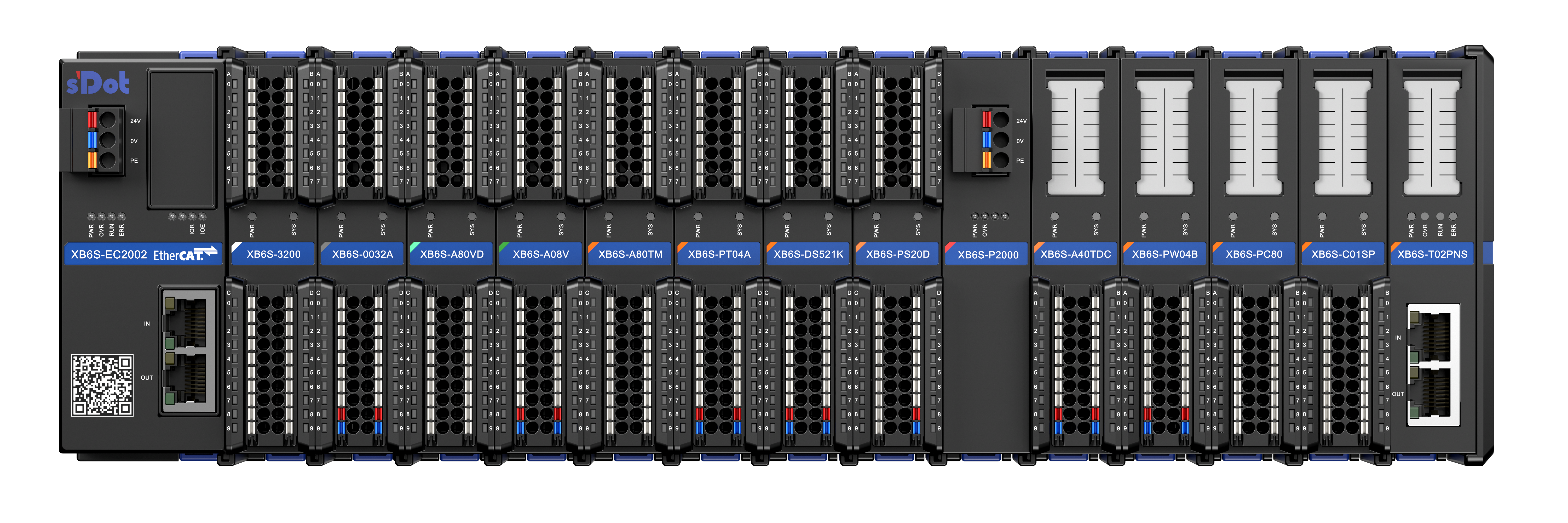

Solidot products used in this case:

XB6S-EI2002, XB6S-1616B, XB6S-0016B, XB6S-0032B, XB6S-C01SP

I. Production Process Overview

Core Workflow of Intelligent Aluminum Drawing Machine:

Preparation → Operation Monitoring → Winding Adjustment → Finished Product Output

Preparation:

Operators configure material specifications, drawing speed, and inverter parameters via HMI to initialize equipment, ensuring precise positioning of aluminum coils at the drawing inlet.

Operation Monitoring:

Real-time monitoring of key parameters (drawing speed, motor current, material tension) with closed-loop control for dynamic adjustment, preventing deformation or breakage to ensure continuous production.

Winding Adjustment:

Dynamic regulation of winding speed and tension based on material length and changes in winding diameter, ensuring uniform coiling while preventing quality issues from loosening or overtightening.

Finished Product Output:

After drawing completion, profiles are smoothly transferred via conveyor to the next process, with production data recorded for quality traceability and process optimization.

II. I/O Module Implementation

Using EtherNet/IP protocol, Solidot modules—digital I/O module XB6S-1616B, digital output modules XB6S-0016B/XB6S-0032B, and serial communication module XB6S-C01SP—connect to Rockwell 1769-series PLC via coupler XB6S-EI2002.

Digital Input Module (XB6S):

Collects emergency stop status, limit switch signals (drawing stroke protection), tension sensor threshold alarms, and proximity switch signals (coil positioning detection). Its NPN/PNP compatibility supports diverse sensor types, ensuring flexible and stable signal acquisition.Digital Output Module:

Controls hydraulic lifting platform positioning, lubrication system solenoid valves, auxiliary conveyor rollers, drawing motors, cooling fans, alarm indicators, winding motor drivers, flying shear solenoid valves, and conveyor motors.XB6S-C01SP:

Reads power meter parameters in real-time and executes PLC control commands.

Collectively enabling precise drawing speed regulation for consistent, stable aluminum profile handling.

III. Solution Comparison

The client’s original bus solution suffered from complex decentralized wiring, low multi-device coordination efficiency, and significant drawing speed fluctuations. Additionally, weak EMI immunity in some modules caused high signal packet loss rates, frequently triggering production issues like roller slippage or material deformation.

After adopting Solidot’s Slice Remote I/O XB6S series:

Enhanced transmission efficiency and EMI resistance

Noticeably improved drawing speed control precision

Reduced tension errors in closed-loop adjustments

Significant improvement in aluminum surface quality

Mixed I/O configuration reduces wiring complexity

IV. High-Reliability Slice Remote I/O Series: XB6S

Solidot’s XB6S Slice Remote I/O series supports multiple bus protocols and integrates motion control/temperature acquisition modules. Key features include:

Rigorous EMC testing for superior interference resistance and zero disconnections

Diagnostic/alarm functions with anomaly logging for intelligent feedback

User-friendly design with simplified maintenance

Recommended Products

XB6S-EI2002

EtherNet/IP filedbus coupler module(Flagship model)

XB6S-1616B

16-channel digital input and output module, Input NPN/PNP compatible, input filter default 3ms, output PNP type

XB6S-0016B

16-channel digital output module, output PNP type

XB6S-0032B

32-channel digital output module, output PNP type

XB6S-C01SP

XB6S Series Serial Communication Module