Application of Solidot's Slice Remote I/O Module XB6S in Semiconductor Dicing Machines

Semiconductor dicing machines are used to precisely cut wafers into individual chip units, requiring processes such as wafer separation, cutting path control, cooling system monitoring, and packaging data recording. The equipment must synchronously process micron-level motion commands and multiple types of signals, demanding stringent real-time performance and interference resistance. Solidot's remote I/O module XB6S series enables high-speed coordinated control via the EtherCAT bus, ensuring a cutting accuracy of ±1μm.

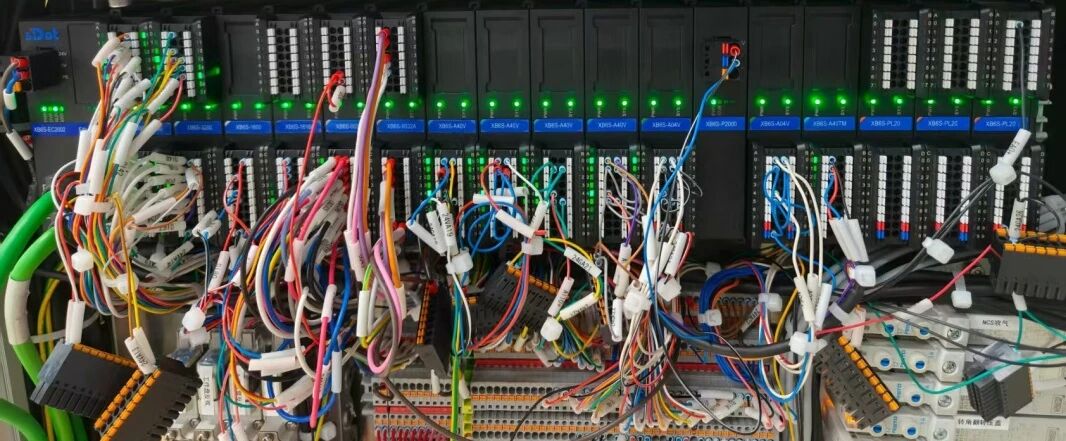

Solidot Products Used in This Case:

XB6S-3200, XB6S-1600, XB6S-1616A, XB6S-0032A

XB6S-A40V, XB6S-A40TM, XB6S-PL20D

I. Production Process Introduction

Automated dicing process: Wafer separation → Cutting control → Cooling monitoring → Packaging recording

【Wafer Separation】

A vacuum adsorption platform secures the wafer, and a robotic arm performs position calibration.

【Cutting Control】

A high-speed spindle drives the grinding wheel along the cutting path to achieve die separation.

【Cooling Monitoring】

Flow meters and encoders provide real-time feedback on coolant flow, while temperature modules simultaneously collect the temperature of the spindle and coolant.

【Packaging Recording】

The system automatically stores temperature, pressure, and flow data after cutting is completed.

II. I/O Module Application Method

The system uses an Advantech MIC-7700 industrial PC (IPC) as the master station, connected to various I/O modules via the EtherCAT coupler XB6S-EC2002. The IPC handles motion control algorithms, temperature PID regulation, and cutting logic operations. The modules are deployed in groups according to signal type:

Digital Input Modules XB6S-3200/XB6S-1600: Collect signals from limit switches, vacuum pressure sensors, and safety doors.

Digital Output Modules XB6S-1616A/XB6S-0032A:输出电磁阀通断控制信号、冷却泵启停指令信号

Analog Voltage Input Module XB6S-A40V: Collects analog voltage signals (0-10V) from spindle current sensors and voltage signals from vibration sensors.

Temperature Acquisition Module XB6S-A40TM: Collects signals from PT100 temperature sensors, providing real-time monitoring of dual-channel temperatures for the spindle and coolant.

Incremental Encoder Counter Module XB6S-PL20D: Receives AB-phase pulse signals from the 5V differential encoder of the flow meter.

Each module focuses on signal acquisition and execution control, working in coordination with the IPC to ensure the high real-time performance and stability of the cutting system.

III. Solution Optimization Results

Compared to the customer's previous all-in-one and Slice I/O solutions from other brands, the XB6S series simplifies the wiring architecture through modular integration, reducing comprehensive operational and maintenance costs while maintaining the same cutting accuracy. The collaborative work of multiple module types, coupled with their anti-interference design, effectively ensures system stability in high-frequency electromagnetic environments, significantly enhancing equipment operational reliability.

IV. Highly Reliable Remote I/O Module XB6S Series

Solidot's remote I/O module XB6S series products are compatible with various bus protocols and feature functional modules for motion control, temperature acquisition, and more. The products undergo rigorous EMC testing, offering superior noise immunity and rejecting disconnections. They support diagnosis, alarms, and exception log recording, providing intelligent feedback for ease of use.

Recommended Products

XB6S-EC2002

EtherCAT filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-1600

16-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-1616A

16-channel digital input and output module, Input NPN/PNP compatible, input filter default 3ms, output NPN type

XB6S-0032A

32-channel digital output module, output NPN type

XB6S-A40V

4-channel analog voltage input module, Single-ended signaling, adjustable range: Disable, -10V~+10V, 0V~10V, -5V~+5V, 0V~5V, and 1V~5V

XB6S-A40TM

4-channel thermal resistance and thermocouple temperature acquisition module

XB6S-PL20D

5V 2-channel incremental encoder counting module with differential signal