Solidot's Simplified Wiring Distributed I/O XBF Application in Lithium Battery Module Pack Lines

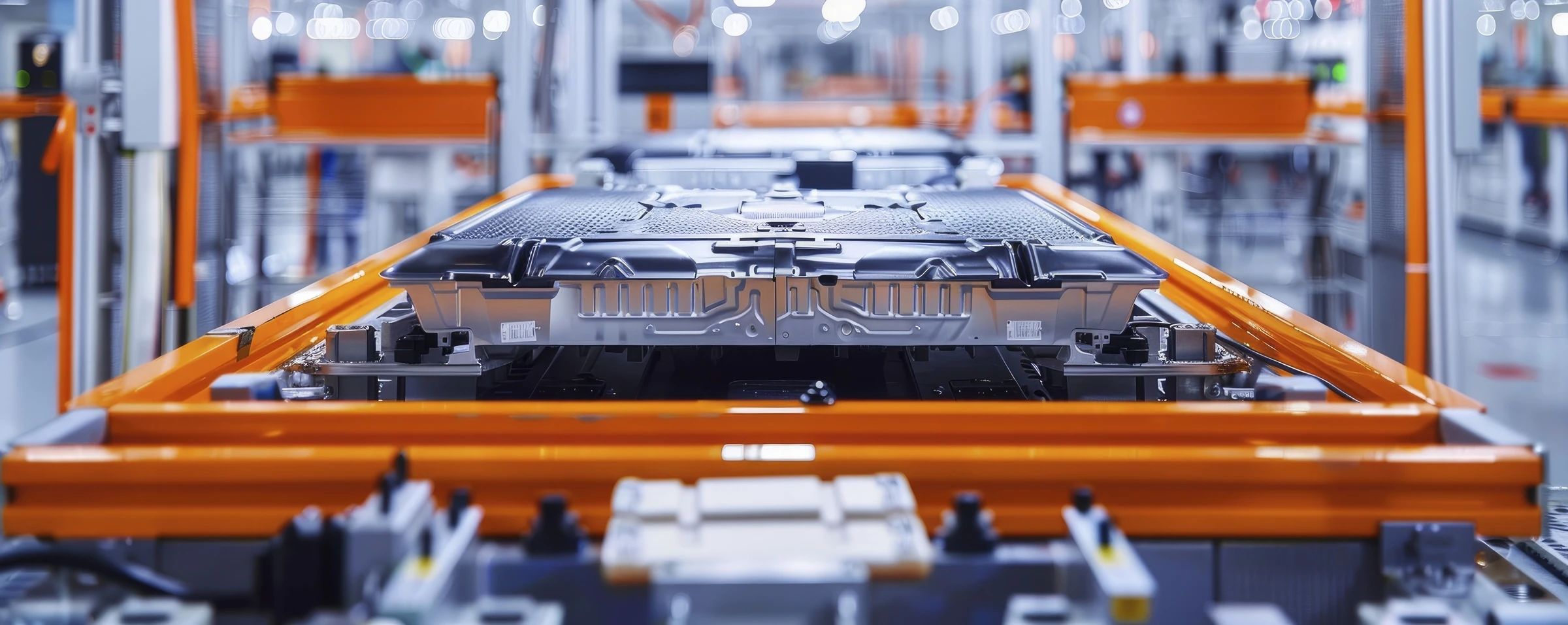

The lithium battery module PACK line is a core process in power battery and energy storage system production, responsible for assembling individual cells into battery modules that meet specific requirements. Its production equipment involves a massive amount of sensor signal acquisition and actuator control, placing extremely high demands on the bus I/O density, wiring efficiency, configuration flexibility, and maintenance convenience of the control system.

Adopting Solidot's Simplified Wiring Distributed I/O series products can significantly simplify wiring, save on cabling, enhance production line flexibility and maintainability, laying the foundation for efficient and stable large-scale production.

Products Used in This Case:

【Distributed I/O】

XBF4-EC04A、XBF2C-0808A、XBF4-1616A

【Slice I/O】

XB6S-3200、XB6S-0032A、XB6S-A40ID

I. Production Process Introduction

The lithium battery module PACK line mainly includes: Cell Feeding & Inspection → Cell Sorting & Matching → Module Stacking & Fixing → Welding → Module Testing & Curing Assembly → Offline Testing & Capacity Grading (Formation).

II. I/O Module Application

XBF Distributed Core + XB6S Remote Expansion

The system uses the EtherCAT protocol, with a Keyence KV-X PLC as the main controller, building the control network via Solidot's XBF EtherCAT protocol coupler XBF4-EC04A. This coupler provides 4 expansion network ports, each supporting up to 16 I/O modules (total 32 modules). Together with the highly reliable Slice I/O XB6S, it enables full-process signal acquisition and control, supporting various topologies (linear, star, hybrid) for flexible line layout.

III. Solution Optimization Results

Cost Optimization: Unified power supply via network cables saved 30% on field-side power cables, terminals, wiring, and labor costs.

Flexible Configuration: XBF coupler's 4-port design supports hybrid topologies and 16 stations per port, enabling flexible layout and easy expansion.

Efficient Maintenance: Intuitive DIP switch addressing, online diagnostics, logging, and firmware upgrades reduce debugging and maintenance time.

IV. Solidot Simplified Wiring Distributed I/O XBF Series Features:

Communication via standard industrial Ethernet cables, no special cables/tools needed.

3-wire power supply for sensors, eliminating terminal blocks and simplifying wiring.

Expansion modules don't consume bus node resources, ensuring high system stability.

Supports linear, star, and hybrid topologies for flexible layout.

Diverse product forms and protection levels for various scenarios.

Rapid customization for point count, structure, and special functions.

Recommended Products

XBF4-EC04A

EtherCAT filedbus coupler module(General Version)

XBF2C-0808A-F

8-channel digital NPN/PNP compatible input and 8-channel digital NPN output module with removable European-style terminals, 3ms default input filtering, and RJ45 communication interface

XBF4-1616A

16-channel digital input with NPN/PNP compatibility and 16-channel digital output with NPN type, featuring removable European-style terminal blocks, 3ms default input filter, RJ45 communication interface

XB6S-EC2002

EtherCAT filedbus coupler module(Flagship model)

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0032A

32-channel digital output module, output NPN type

XB6S-A40ID

4-channel analog current input module, Differential signaling , adjustable range: Disable, 4mA~20mA, 0mA~20mA, and-20mA~+20mA

XB6S-C01SP

XB6S Series Serial Communication Module