The application of Solidot XB6 series EtherNet/IP slice I/O module in the automatic syringe assembly machine in the medical industry

Syringes are very commonly used medical equipment with huge consumption. Although syringe needles seem to be extremely small, the production process is very complicated. First, the stainless steel material must be processed and welded into a tubular structure, and then the needle tube must be cold-processed several times to increase its hardness. Then, it must be cut and rinsed several times to be sharpened into a needle with a sharp top. Finally, it can enter the assembly stage after passing the test.

If the needles are assembled manually, the efficiency is low and it is easy to cause injuries, and the yield rate of the product cannot be improved. In order to solve the above problems, the automatic needle assembly machine came into being, which greatly improved the assembly efficiency and realized mass production. This case will focus on the application of the XB6 series EtherNet/IP protocol plug-in I/O module of SOLIDOT Technology in the automatic assembly production process of needles.

Description of the automatic assembly process for injection needles

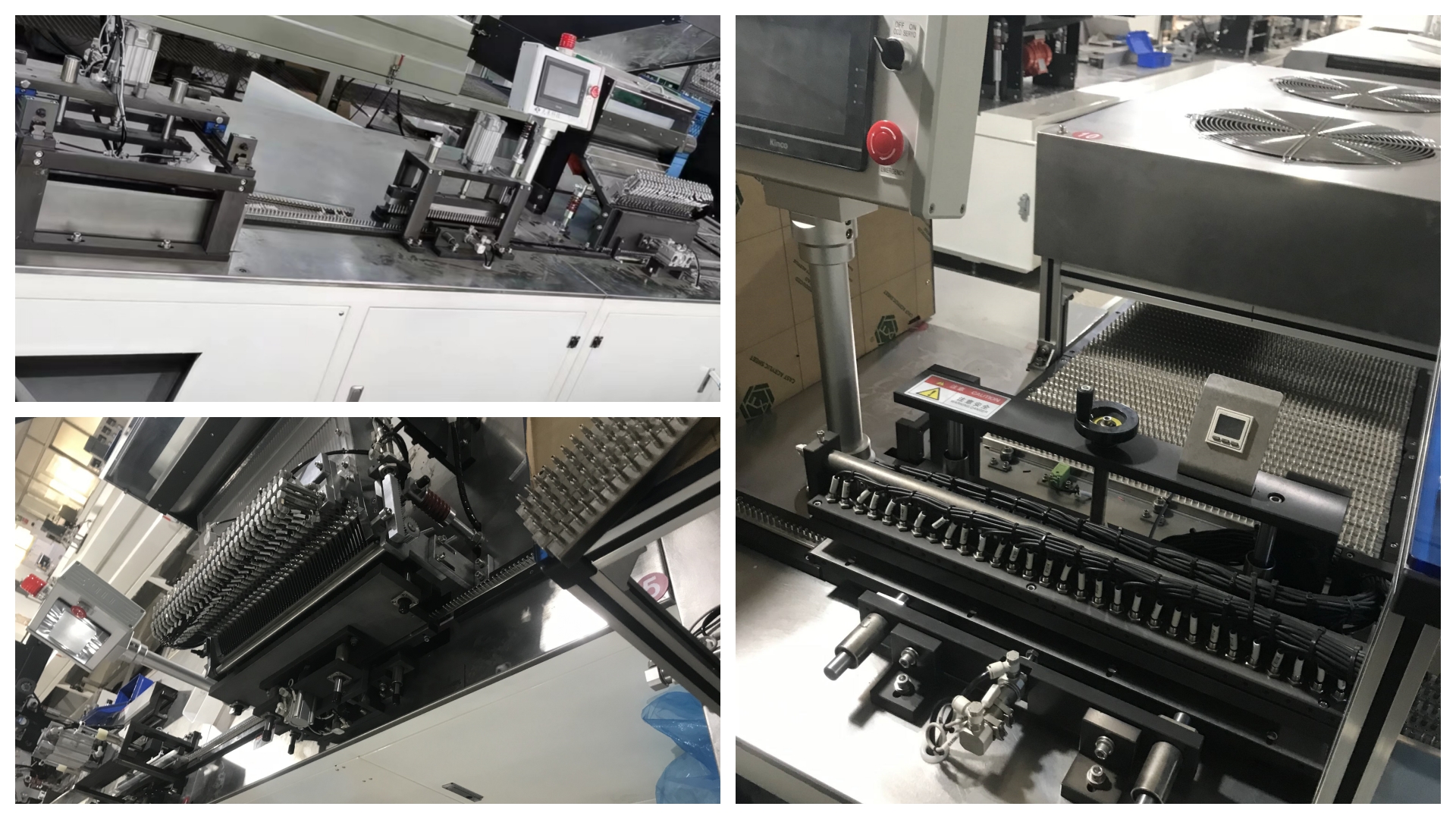

▲ On-site equipment picture

The tooling strip is used to place the needle holder, insert the needle tube, and use the KEYENCE fiber optic sensor head and fiber optic amplifier to position the needle tube to ensure that the needle tube is in the right position before dispensing. Then, the equipment pressure is controlled by controlling the on/off of the SMC solenoid valve, and the appropriate glue output and dispensing speed are set. The needle tube and the base are bonded together and then put into the oven for drying. The injection needle after dispensing needs to be detected for burrs and blockages using an image measuring instrument to remove unqualified waste. In addition, the injection needle needs to be siliconized to minimize its friction during the puncture process and increase the sharpness of the needle tip. Finally, the needle tube is fitted with a sheath and ready to be discharged.

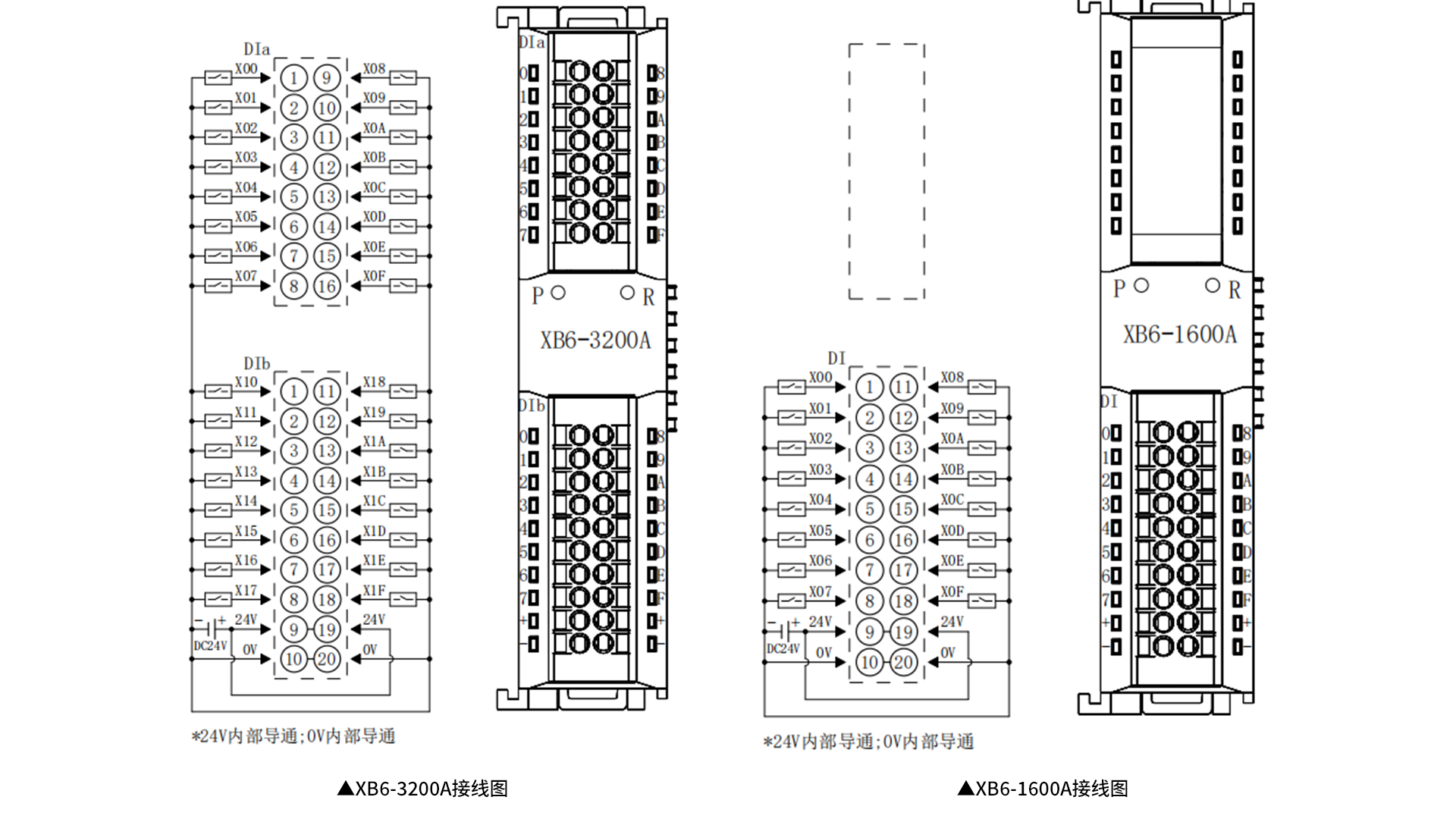

During the entire production process, a large number of photoelectric sensors, fiber optic sensors, solenoid valves, cylinders, image measuring instruments, etc. need to be connected to the control system. The number of signals is large and the equipment locations are relatively scattered. The use of XB6 series plug-in remote I/O modules to connect can effectively solve the problem. The sensor detection signals in production are collected by XB6-3200A and XB6-1600A modules, and the actuator signals such as cylinders are controlled by XB6-0032A modules.

Installation photo of remote I/O module in the cabinet of SOLIDOT Technology

▲ XB6-3200A、XB6-1600A、XB6-0032A

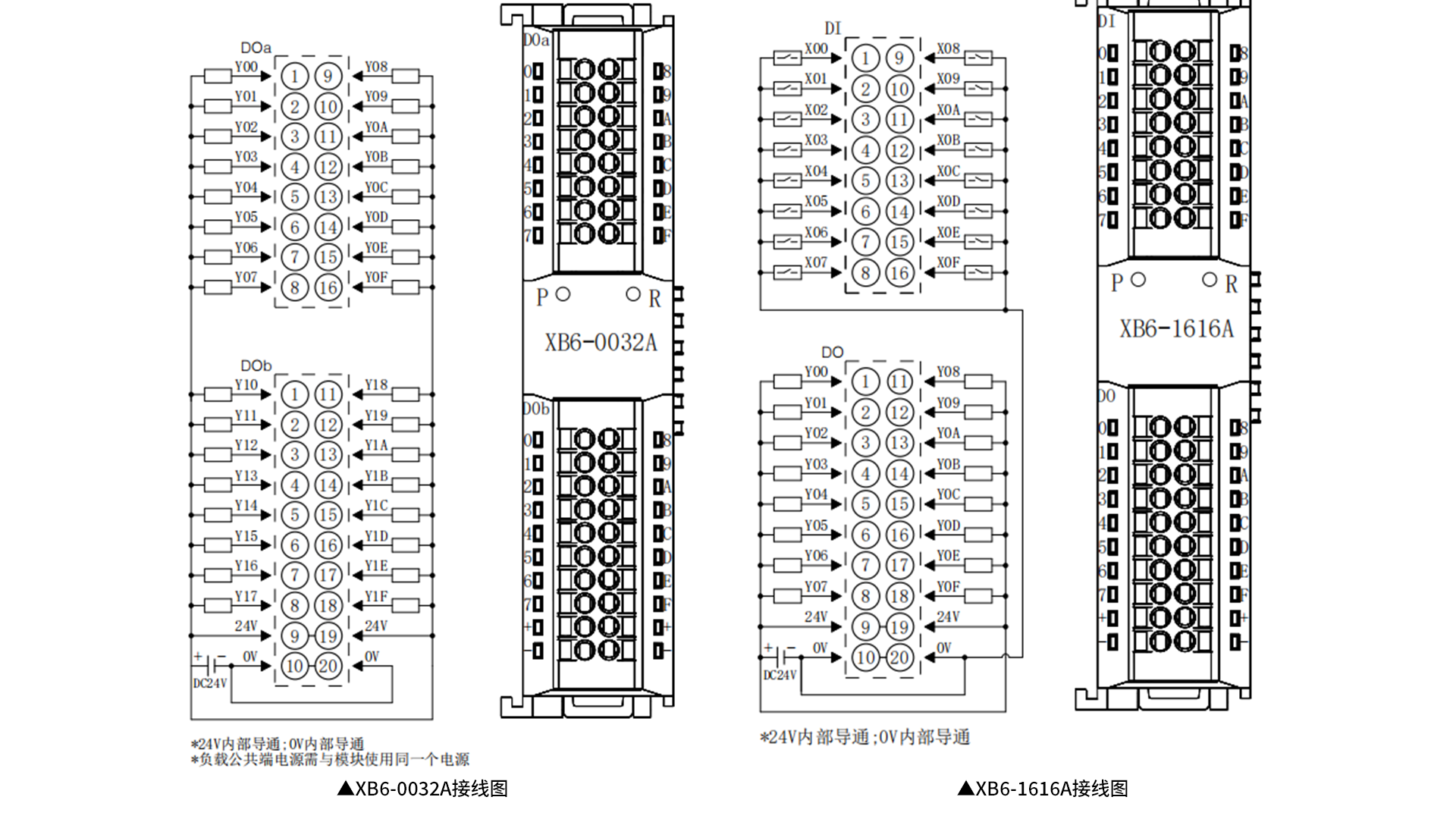

Wiring diagram of remote I/O module of SOLIDOT Technology

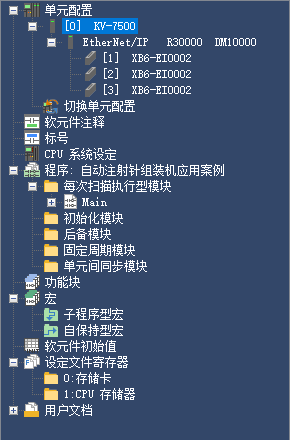

【PLC software configuration】

▲ Configuration screen

Introduction to EtherNet/IP Protocol Products of SOLIDOT Technology

The XB6 series EtherNet/IP protocol I/O module of SOLIDOT Technology is only 106*61*47mm in size. It is compatible with most EtherNet/IP master stations such as KEYENCE, OMRON, Schneider, ABB, etc. It has a high-speed X-bus backplane bus, a maximum scan cycle of 1ms, and a protection level of IP20.

In the application of the above-mentioned automatic injection needle assembly machine, the on-site solution provided by SOLIDOT Technology meets the needs of scattered device connection and a large number of signal acquisition. The I/O module also has the following advantages:

*Small module size, saving space in the control cabinet

*Simple configuration, saving engineering design time

*Easy to install and wire, shorten assembly time

*Flexible module model combination, providing customers with flexible application solutions

* Up to 32 I/O modules can be expanded to adapt to various application scenarios

Over the years, SOLIDOT Technology has been committed to the automation industry and has accumulated profound technical experience in the field of bus products. As domestic independent products have become increasingly mature and stable in the past two years, SOLIDOT Technology's digital solutions will enter more industries and continue to receive more and more praise from customers.

Recommended Products

XB6-3200A

32 DI, NPN, European style terminal

XB6-1600A

16 DI, NPN, European style terminal

XB6-0032A

32 DO, NPN, 0.5A, European style terminal

XB6-EI2002ST

EtherNet/IP Coupler kit (with power supply, end cover )

XB6-1616A

16 DI 16DO, NPN, 0.5A, European style terminal