Application of Solidot C2S Series PROFINET Bus Valve Island in Industrial Pollution Control Systems

Industrial pollution control is a core field in environmental protection, involving processes such as exhaust gas purification, wastewater treatment, and solid waste recovery. These demand extremely high stability, response speed, and device integration in automation control. Traditional pneumatic solutions reveal limitations when handling complex processes and frequent maintenance, while bus valve islands offer efficient and reliable alternatives with simplified wiring and commissioning.

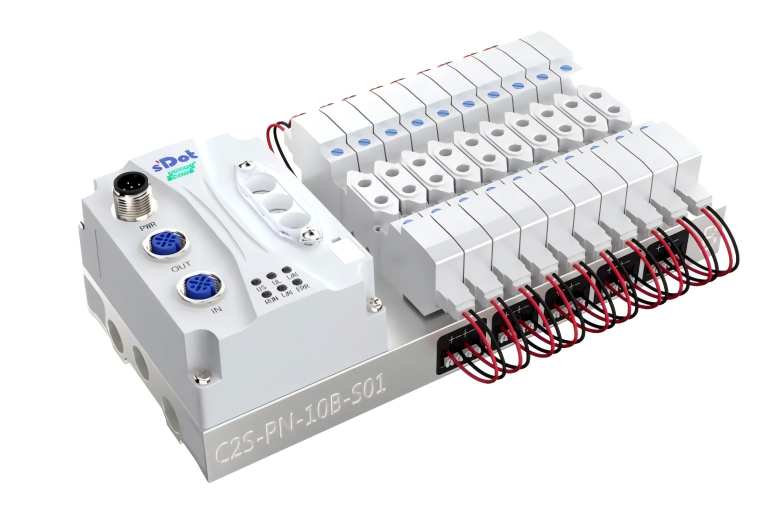

Product Used: C2S-PN-10B-S01

I. Production Process

A client in environmental protection specializes in industrial pollution control systems with core processes:

(1) Exhaust Gas Treatment

Collection & Pretreatment: Fans and pipelines collect exhaust; spray systems precisely control water flow/valves to remove particles.

Adsorption & Catalysis: Activated carbon tank valves switch by sequence; catalytic reactor valves dynamically adjust gas flow/temperature.

Emission: Real-time exhaust valve control ensures compliance.

(2) Wastewater Treatment

Purification: Valves/pumps in sedimentation tanks and bioreactors adjust flow paths based on pH/turbidity sensors.

Resource Recovery: Membrane separation valves enable component recycling.

(3) Solid Waste Management

Sorting & Conveying: Pneumatic valves direct waste to incineration, landfill, or recycling.

II. Bus Valve Island Application

Using PROFINET protocol, the C2S-PN-10B-S01 connects to Siemens S7-300 PLC to achieve:

Exhaust control: Spray valves, adsorption tank valves, and catalytic reactor flow valves.

Wastewater control: Bioreactor inlet/outlet valves with dynamic flow adjustment; multi-channel membrane valves.

Solid waste sorting: 10-bit dual solenoid valves for rapid path switching.

III. Optimization Results

Versus traditional wiring complexity and maintenance difficulties, Solidot’s C2S bus valve island delivers:

Simplified Wiring: M12 interfaces reduce cabling by 80% with integrated 10-bit valves.

Efficient Maintenance: LED status indicators and channel diagnostics cut troubleshooting time by 60%.

The solution is now deployed in next-gen environmental equipment, driving smart manufacturing transformation.