Application of Solidot Profinet protocol products in the logistics

In today's society, almost everyone owns a smartphone, which has brought unprecedented convenience to our lives. The most typical example is shopping on e-commerce platforms. After placing the order, the reason why we can receive the goods so quickly is due to the development of logistics. Especially for fresh fruits and other packages that are not easy to transport over long distances, the entire process is controlled by the intelligent digital refrigerated three-dimensional warehouse in the logistics chain.

When it comes to intelligence and digitalization, of course it is inseparable from the participation of remote I/O. Solidot remote I/O module has mature implementation experience in the above scenarios and has provided a number of high-quality solutions for the industry. This article will introduce in detail the application of Solidot Technology PROFINET network remote I/O in logistics and warehousing .

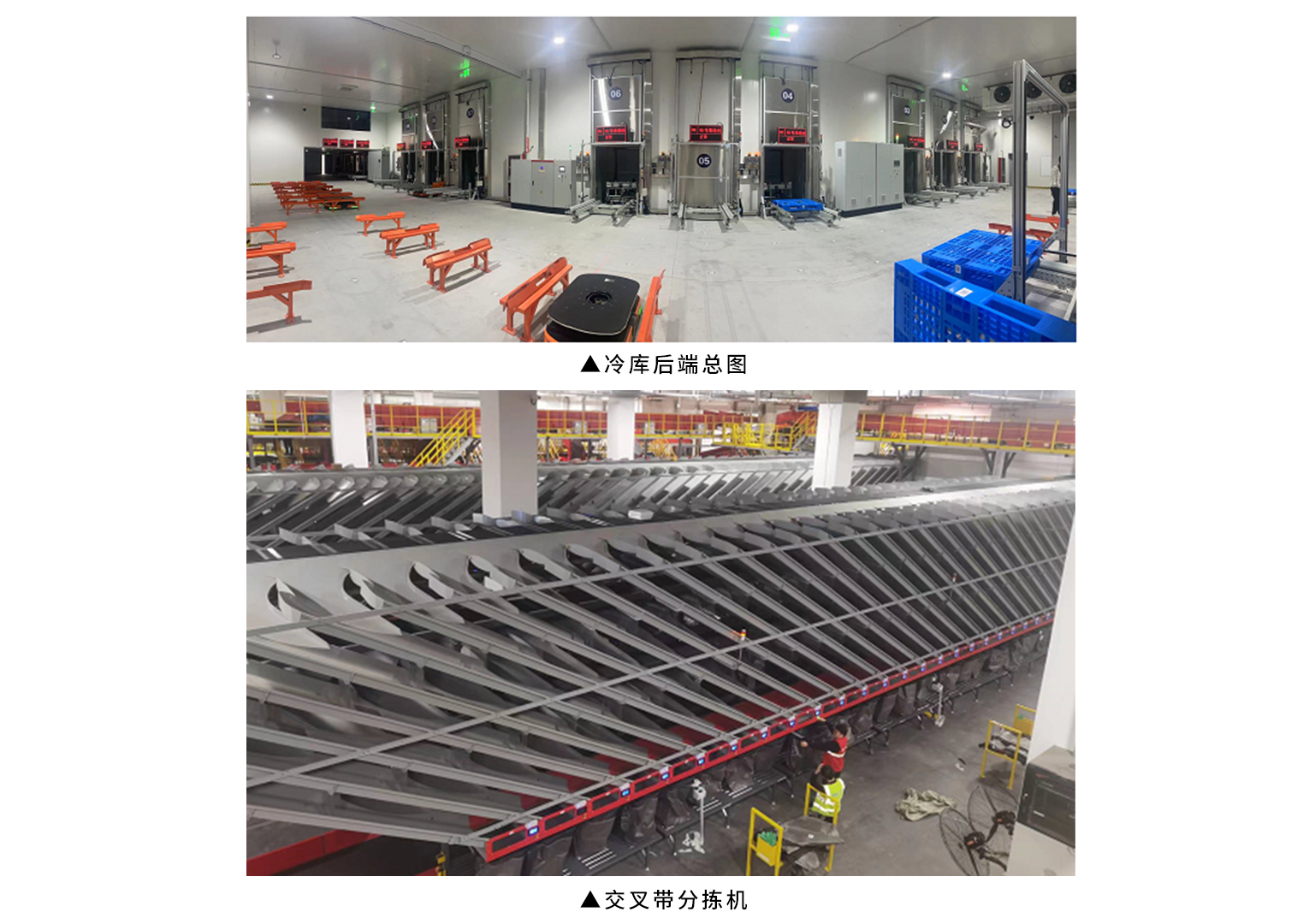

[Common logistics sorting equipment and field description]

Large-scale sorting centers include: belt retractors, belt conveyors, single-piece separation, 6-sided sweeps, balance wheel sorters, cross-belt sorters, introduction tables, narrow-band sorters, etc.; intelligent warehousing equipment includes: belts Telescopic machines, belt conveyors, tunnel stackers, AGV systems, etc.

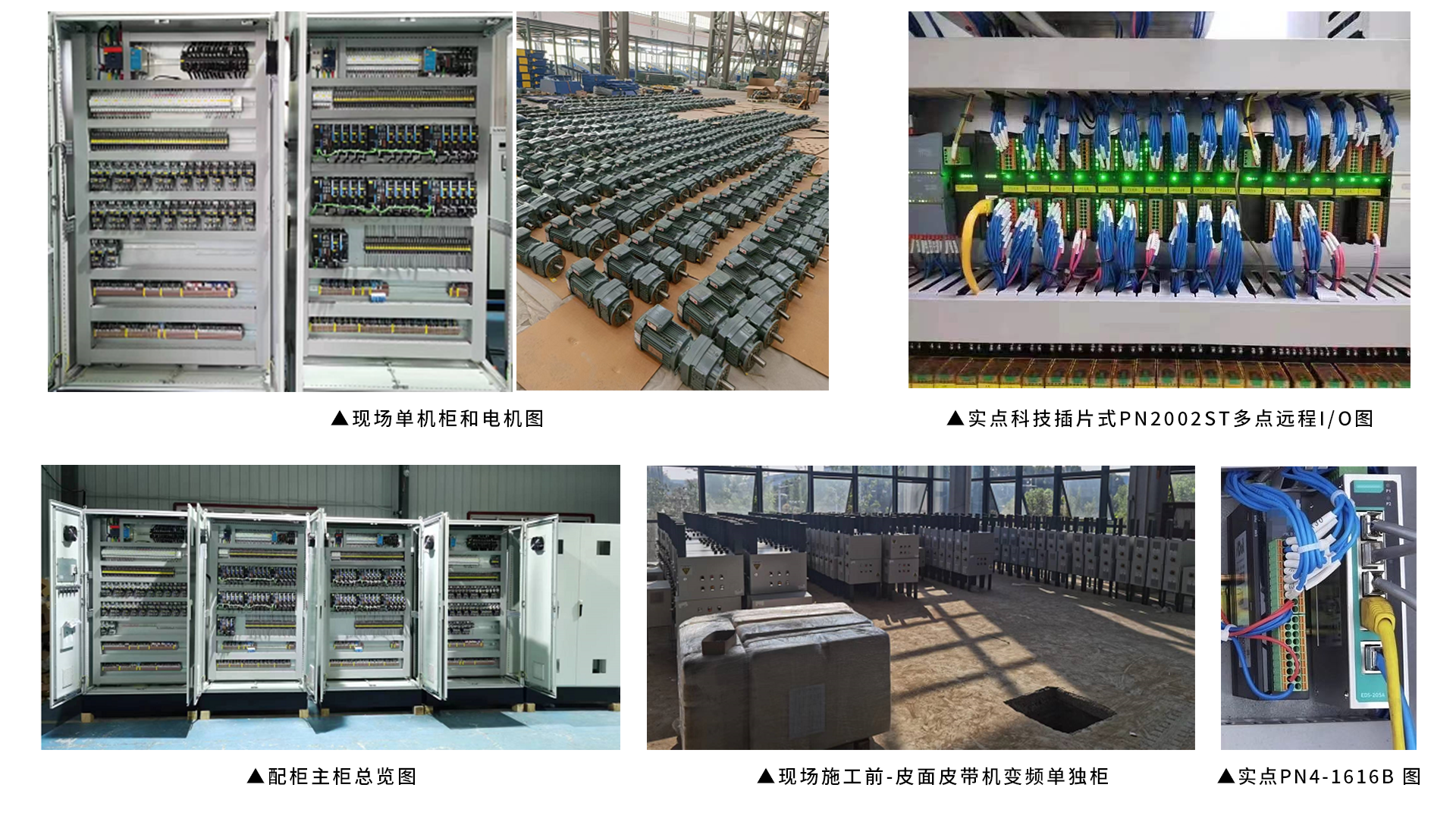

The "brain system" of these devices mainly uses Siemens PLC S7-1500, and the stand-alone machine uses PLC S7-1200. Other remote I/Os use remote I/Os from Solidot Technology. Because in actual work, there are a large number of conveyors in the sorting center, each belt requires a frequency converter to adjust the speed, and the signal of each belt must be collected. However, since the distance between the equipment and the main distribution cabinet is also long, so the remote I/O of PROFINET communication of Solidot is used for control, which solves the above problems.

In addition, the three-dimensional warehouse has many station signals and is far away from the main cabinet. The site also uses an integrated module PN4-1616B of the PROFINET communication protocol of Solidot to solve it. The integrated type is mainly used for some stand-alone equipment or some workstations with relatively few points. For the collection of a large number of concentrated I/O points, the slice structure is used. The models are: coupler XB6-PN2002ST , 32-point input module XB6 -3200B , 32-point output module XB6-0032BW.

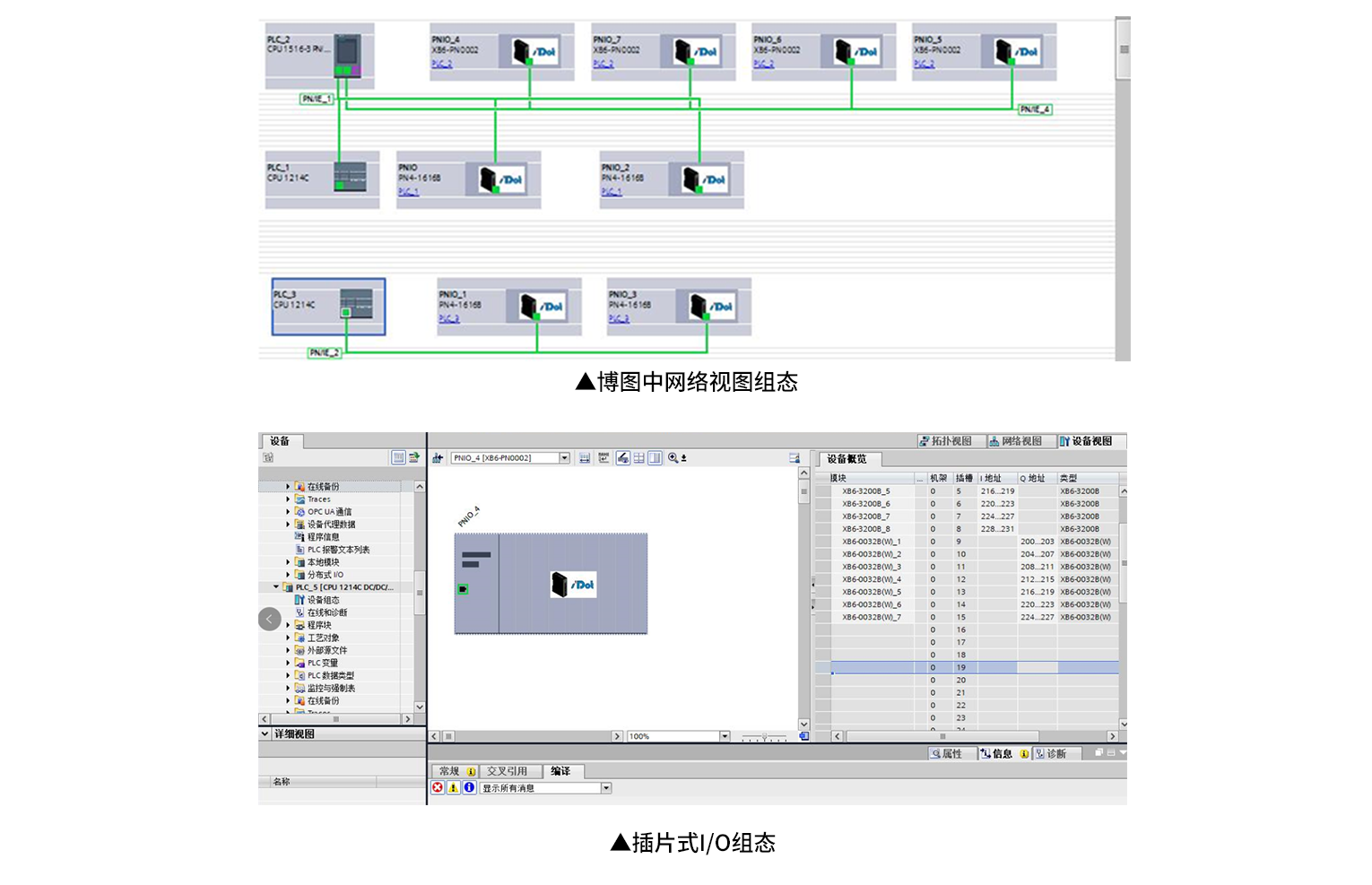

[Remote configuration of Solidot in TIA PORTAL V16]

We are using Siemens CPU 1516 PLC, and we need to add the GSD file of the Nanjing solidot remote module in the Siemens Portal software.

Add the GSD file of Solidot Technology's remote I/O in the Porto software [options], as shown below:

▲ Add GSD file to Portal

Finally, configure in TIA PORTAL software, and configure accordingly according to the actual number of peripheral I/O points, especially slice I/O, as shown below:

【Summarize】

As a well-known automation service supplier in China, Solidot has an early presence in the distributed I/O field, has deep experience, and has excellent R&D technology.

In this case, the field equipment is large in size and has a long queue. It uses fieldbus I/O from Solidot and only requires a 24V power cable and a network cable, which can meet many customer needs such as simple wiring, convenient construction, and easy maintenance. Among them, the Solidot integrated I/O module PN4-1616B is aimed at small devices and scenarios with a small number of points, while the slice XB6-PN2002ST module can be freely matched with input and output and can be combined with a large number of points. The quality of both is stable, and it is flexible and convenient in adaptation. It solves customer pain points and can perfectly replace overseas brands, achieving a win-win situation of efficiency and economy.

Recommended Products

PN4-1616B

PROFINET, Intergrated I/O, 16DI, 16DO, PNP, 0.5A

XB6-3200B

32 DI, PNP, European style terminal

XB6-PN2002ST

PROFINET Coupler kit (with power supply, end cover )