Application of Solidot's Remote I/O Module XB6S in Automotive Gas Generator Assembly Lines

The gas generator for automotive airbags, as a safety-critical component, imposes stringent requirements on its assembly line regarding part feeding rates, coordinated assembly actions, and process control stability. Adopting the XB6S series Remote I/O Modules effectively simplifies equipment wiring, enhances communication stability, and ensures product quality and production efficiency.

Solidot Products Used in This Case:

XB6S-PN2002, XB6S-1600, XB6S-0016B, XB6S-A04I

I. Production Process Overview

Precision Assembly Flow: Empty Tray Positioning → Subassembly Transfer → Component Assembly → Vibratory Bowl Feeder Supply → Performance Testing → Laser Marking & Packaging

Empty Tray Positioning: The conveyor system transports empty trays to the workstation; positioning sensors trigger clamping devices to secure them.

Subassembly Transfer: Controls conveyor belt speed, start/stop to ensure sequenced transfer to the assembly station.

Component Assembly: Robotic arms perform grasping and assembly actions based on visual recognition.

Vibratory Bowl Feeder Supply: Feeder orients and sorts small parts; requires stable, adjustable frequency for smooth feeding.

Performance Testing: Conducts electrical parameter and functional tests on assembled units.

Laser Marking & Packaging: Qualified products undergo laser marking and automatically enter the packaging process.

II. I/O Module Application

The production line control system utilizes the PROFINET bus protocol, centered on a Siemens S7-1500 PLC as the master station. Solidot's PROFINET Coupler XB6S-PN2002 connects the digital input module XB6S-1600, digital output module XB6S-0016B, and analog output module XB6S-A04I, forming a highly efficient, low-latency, and high-noise-immunity control network.

XB6S-1600: Collects signals for empty tray presence, fixture positioning status, vibratory feeder operation feedback, and safety interlocks.

XB6S-0016B: Controls vibratory feeder motor start/stop, transfer mechanism actions, and test station actuators.

XB6S-A04I: Outputs current analog signals for product testing stages.

The PLC centrally dispatches and processes data, enabling command issuance and full-process coordination.

III. Solution Optimization Results

Implementing Solidot's XB6S series Remote I/O Modules significantly improved overall communication stability on the assembly line, simplified wiring, enhanced equipment maintainability and scalability, and effectively reduced the line's comprehensive costs.

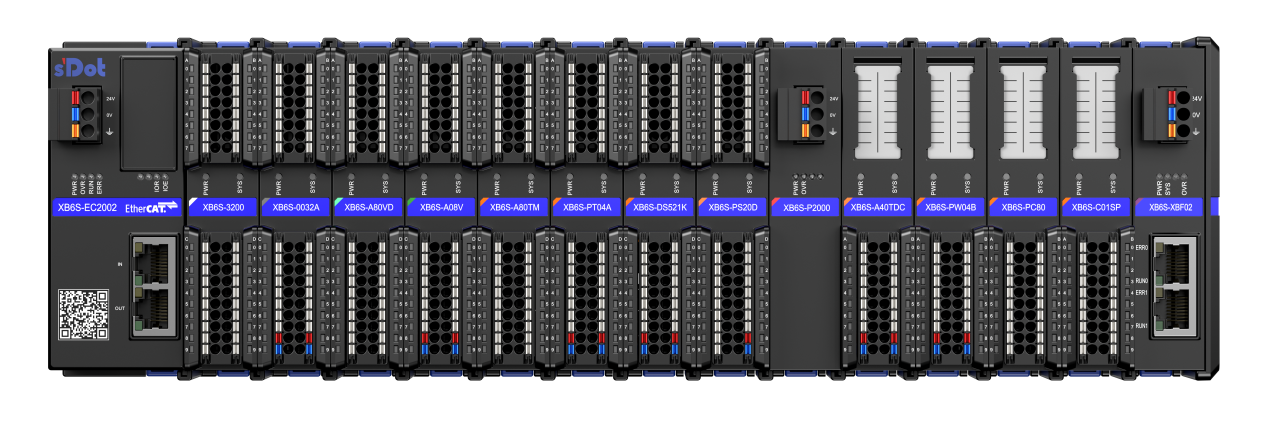

IV. High-Reliability Remote I/O Module - XB6S Series

Solidot's XB6S Series Remote I/O Modules support multiple bus protocols and include function modules for motion control, temperature acquisition, etc. Products undergo rigorous EMC testing, offering superior noise immunity and eliminating disconnections. They support diagnostics, alarms, and anomaly logging for intelligent feedback and ease of use.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module(Flagship model)

XB6S-1600

16-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0016B

16-channel digital output module, output PNP type

XB6S-A04I

4-channel analog current output module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA