Common errors and solutions for Profinet communication diagnostic alarms

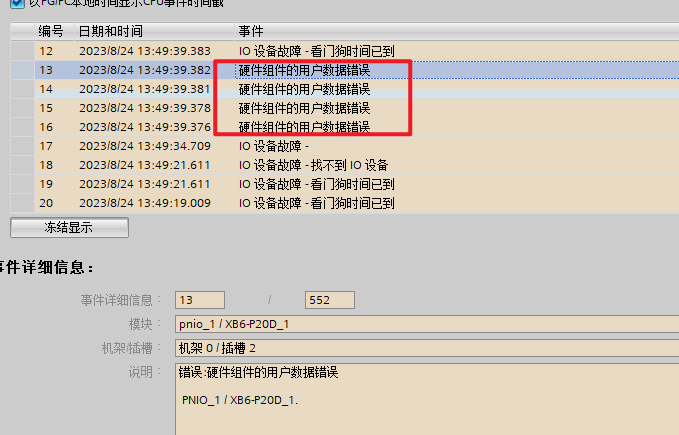

01 Online diagnosis reports that the user data of the hardware component is wrong and the device configuration does not sup

Solution:

(1) Check the module terminal cover;

(2) Check whether the configuration module is consistent with the actual assembly module sequence model.

02 Network view, device view interface displays a black exclamation mark

Solution:

PLC goes offline and downloads hardware configuration

03 Online diagnostics reports partner error - no neighbor detected, wrong port partner

Solution:

(1) The PLC goes offline, deletes the connections in the topology view and downloads it;

(2) The PLC goes offline, connects correctly and downloads.

04 Watchdog timeout

Solution:

(1) Check whether the network cable is loose;

(2) After confirming that there is no abnormality in the network cable, ping the IP. Generally, the physical link is 1~2ms. Check whether there is a long delay. If so, you need to check the network environment.

(3) Check whether there is a ring network in the topology;

(4) Check switches and routers;

(5) Check whether there are any devices affecting the switch and router. You can plug in the devices one by one to observe;

(6) Increase the size of the watchdog appropriately.

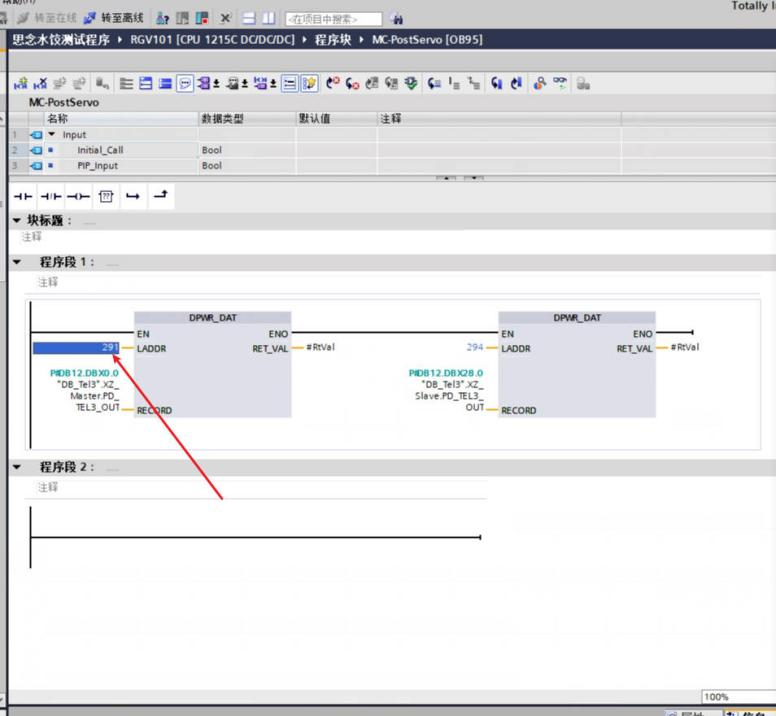

05 PROFINET acyclic service timeout

Solution:

(1) The hardware identifier of IO is not called in the program;

(2) Add a new IO configuration and then delete the original IO configuration. The purpose of this operation is to allow the PLC to assign a new hardware identifier to avoid the problem of duplication between the hardware identifier called by the program and the hardware identifier of the IO module.