Application of Solidot Slice Remote I/O Module XB6S in Filling and Weighing Systems

Filling and weighing systems are critical equipment in industries such as food and chemicals, responsible for quantitative liquid filling. With rising demands for production efficiency and precision, these systems require rapid start-stop control, real-time weight acquisition, multi-valve coordination, and full-process monitoring, imposing stringent requirements on real-time response and signal stability of control systems. The adoption of Solidot's XB6S Remote I/O Modules effectively simplifies wiring, laying the foundation for stable and efficient filling.

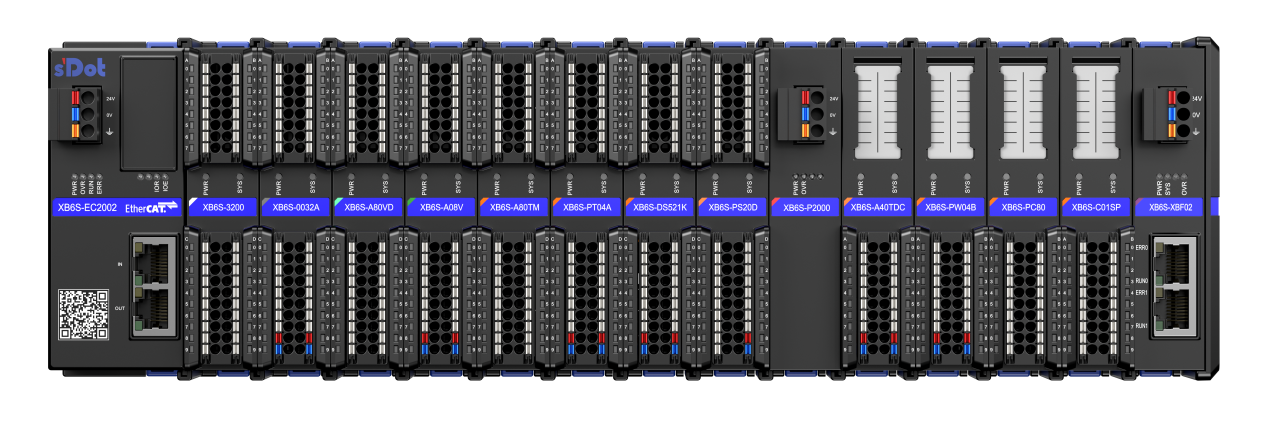

Products Used in This Case

XB6S-1600, XB6S-3200, XB6S-0012J/6

XB6S-A40I, XB6S-A80I, XB6S-A04I, XB6S-A08I

XB6S-A40TM, XB6S-A80TM, XB6S-C01SP

PART ONE: Production Process Overview

Filling Workflow: Empty Can Positioning → Filling Execution → Weighing Regulation → Full Can Detection/Label Printing

Empty Can Positioning: Conveyor transports cans to stations; proximity switches detect positioning signals to trigger clamping mechanisms.

Filling Execution: Controls conveyor speed/start-stop, sequences main/fine-tuning valves based on preset volumes for rapid filling and precision replenishment.

Weighing Regulation: Load cells acquire weight in real-time; system dynamically adjusts valve actions to ensure accuracy.

Full Can Detection/Label Printing: Valves close upon reaching target weight; confirms fill integrity, releases clamps after leak check, and prints traceability labels.

PART TWO: I/O Module Implementation

PROFINET bus protocol with Siemens S7-1500 PLC as master. Coupler XB6S-PN2002connects:

Digital Input(XB6S-3200、XB6S-1600): Captures can-positioning, valve limits, E-stop, and safety door signals.

Relay Output(XB6S-0012J/6): Controls motor start-stop, valve actuation, and alarm signals.

Analog Modules(XB6S-A40I、XB6S-A80I、XB6S-A04I、XB6S-A08I): Transmits multi-station weight sensor/valve current signals with anti-interference stability.

Temperature Modules(XB6S-A40TM、XB6S-A80TM): Monitors material temperature and critical equipment hotspots.

Serial Module(XB6S-C01SP): Connects label printers via RS485.

PART THREE: Optimization Results

Solidot’s XB6S Remote I/O Modules enabled:

Analog modules acquire weight signals locally with high anti-interference accuracy.

Simplified wiring enhances maintainability.

Slice I/O design allows on-demand expansion, reducing upgrade costs and commissioning time.

PART FOUR: XB6S Series Highlights

Supports multiple bus protocols with motion control/temperature acquisition modules.

Passes rigorous EMC tests with superior noise immunity and zero disconnections.

Diagnostics, alarms, and exception logs enable smart feedback and ease of use.

Recommended Products

XB6S-PN2002

PROFINET filedbus coupler module(Flagship model)

XB6S-1600

16-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-3200

32-channel digital input module, input NPN/PNP compatible, input filter default 3ms

XB6S-0012J/6

12-channel relay output module

XB6S-A40I

4-channel analog current input module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA

XB6S-A80I

8-channel analog current input module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA

XB6S-A04I

4-channel analog current output module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA

XB6S-A08I

8-channel analog current output module, Single-ended signaling, adjustable range: Disable, 4mA~20mA, 0mA~20mA

XB6S-A40TM

4-channel thermal resistance and thermocouple temperature acquisition module

XB6S-A80TM

8-channel thermal resistance and thermocouple temperature acquisition module

XB6S-C01SP

XB6S Series Serial Communication Module