Communication Method Between Solidot Integrated I/O Modbus TCP Protocol Module and Kinco HMI

Solidot's Integrated I/O Modbus TCP Protocol Module MT4 series is widely used in industries such as cold chain logistics, automotive, and machining, providing flexible and efficient industrial bus solutions for small-scale wiring scenarios. For this reason, customers typically use it without a PLC, directly establishing communication with HMIs. Below, using the MT4-1616A(16-channel DI, 16-channel DO, NPN) as an example, we explain the communication method between the MT4-1616A and Kinco HMI.

↑ Solidot Integrated I/O Modbus TCP Protocol Module MT4-1616A

I. Network Topology

The MT4-1616A’s default factory IP address is 192.168.1.120. The topology is as follows:

II. Configuration via Kinco DTools Software

1. Create a New Project

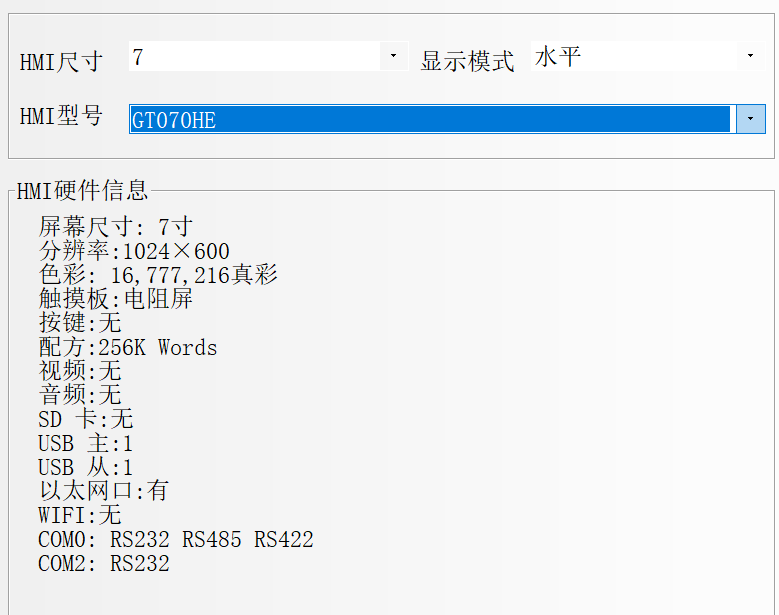

Select the corresponding HMI model and click "OK".

2. Modbus TCP Client/Server Configuration

Modbus TCP Client (Master) Configuration

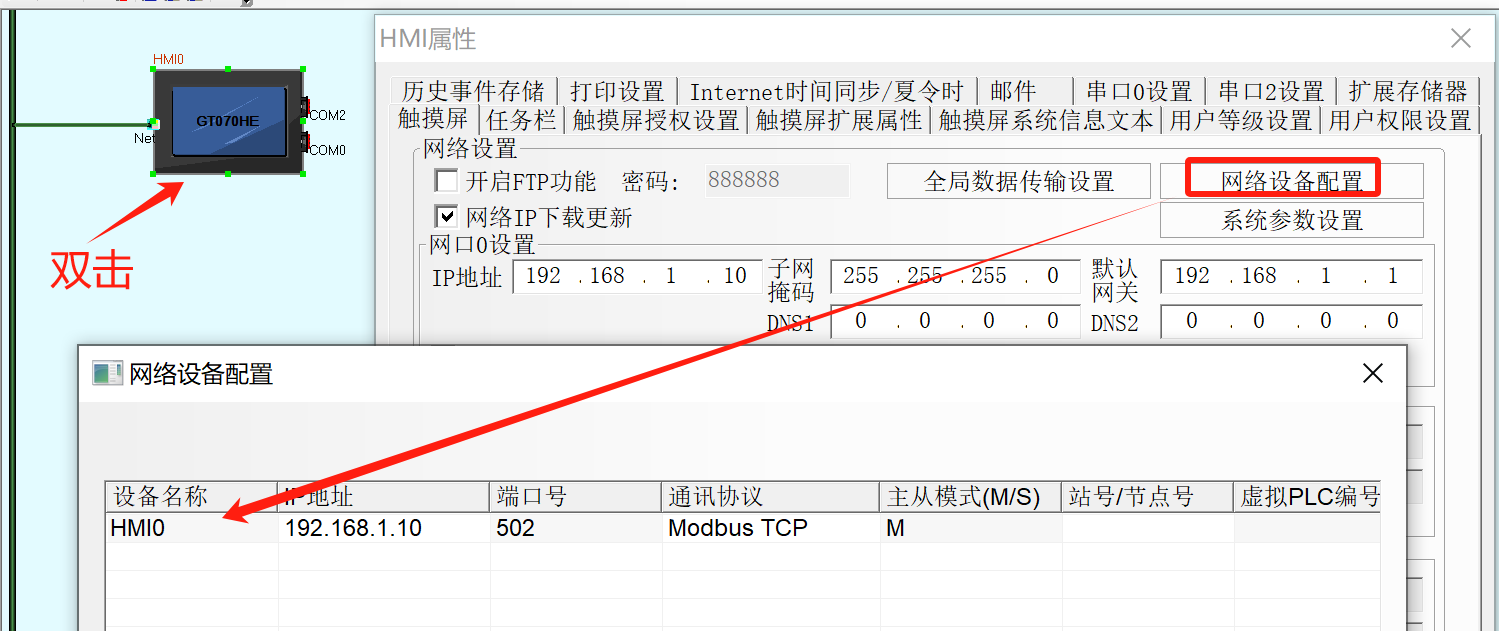

Double-click the HMI icon → Network Device Configuration → Set communication protocol to Modbus TCP.

Modbus TCP Server (Slave) Configuration

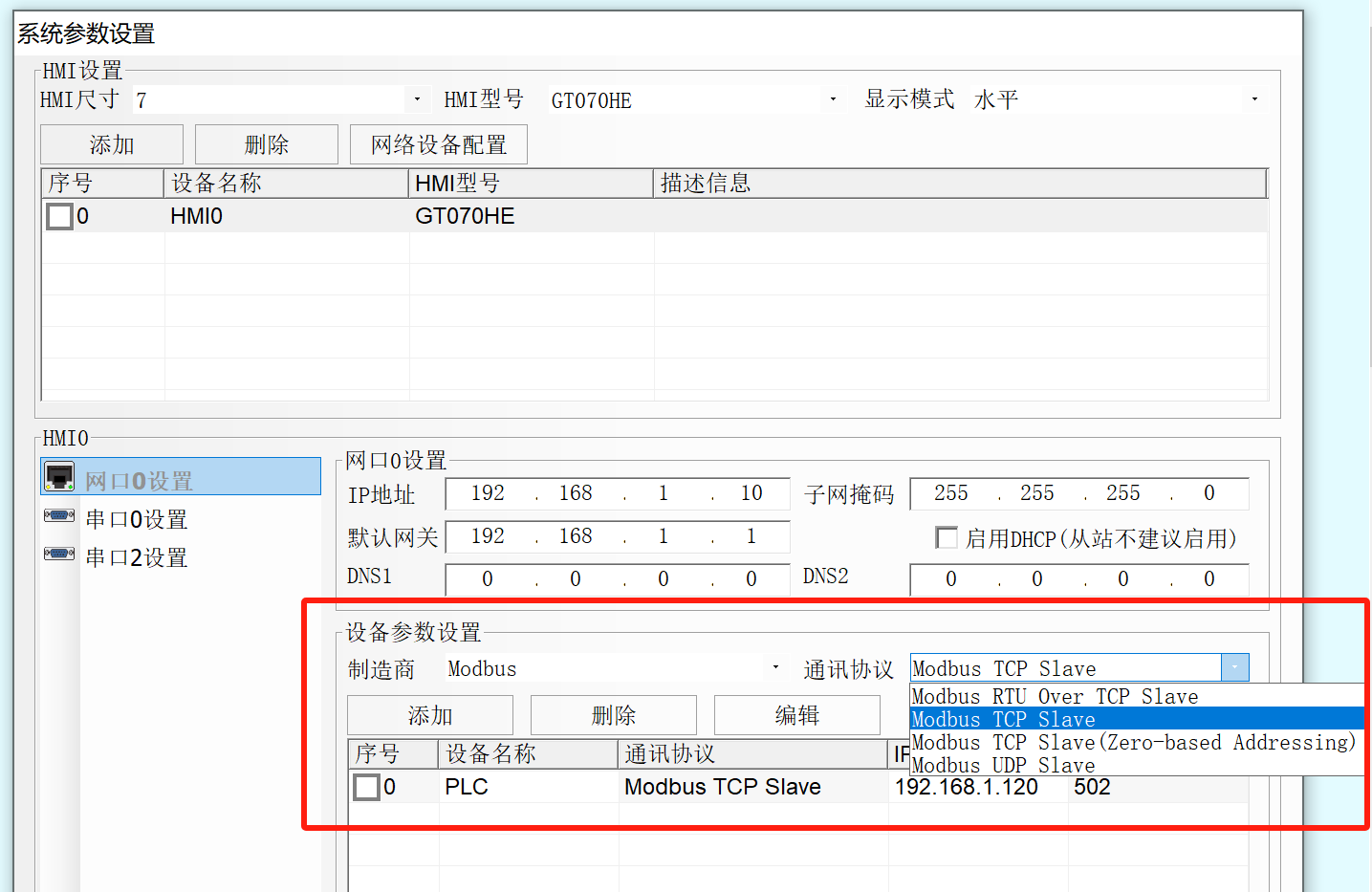

Go to System Parameters → System Parameter Settings → Device Parameter Settings → Select Manufacturer: Modbus, Protocol: Modbus TCP Slave → Add.

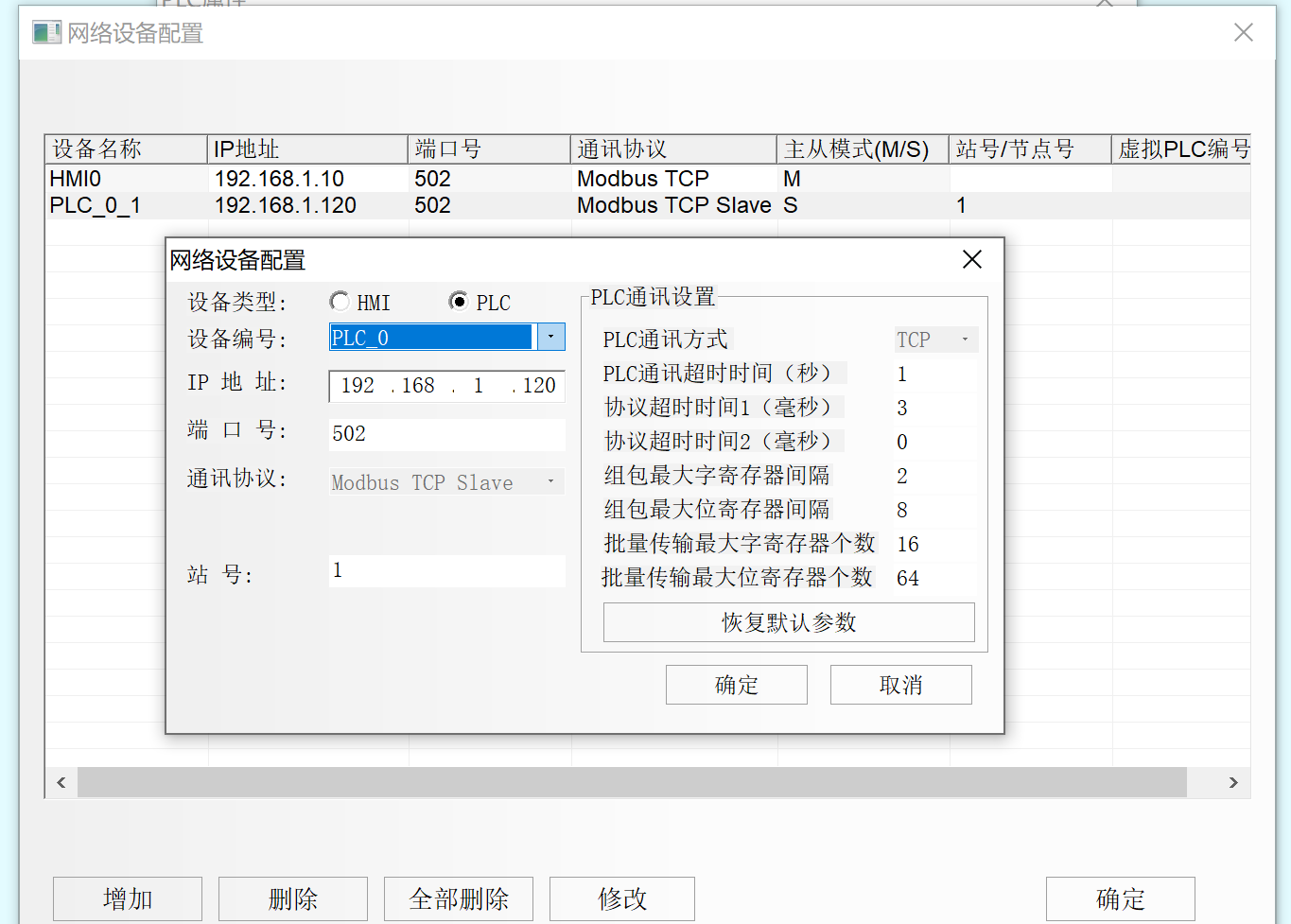

3. Set Server IP Address and Port

Configure the server (MT4 module) IP address and port. The factory defaults are:

IP Address: 192.168.1.120

Port: 502

Note: Ensure the HMI and MT4 module IP addresses are on the same subnet. In this example:

HMI IP: 192.168.1.10

MT4 IP: 192.168.1.120

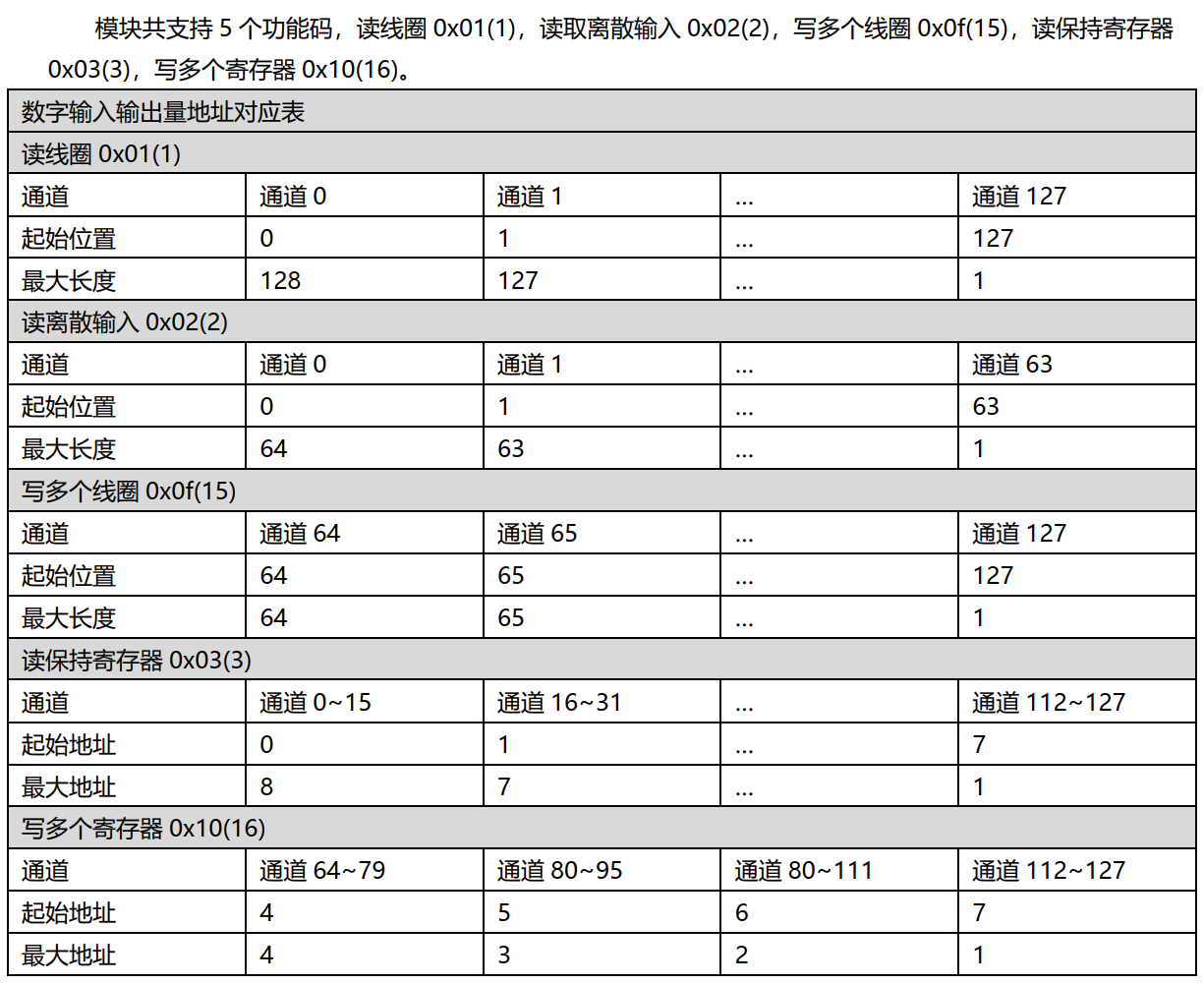

4. MT4-1616A I/O Address Mapping

Refer to the MT4 product manual for Modbus function code mappings:

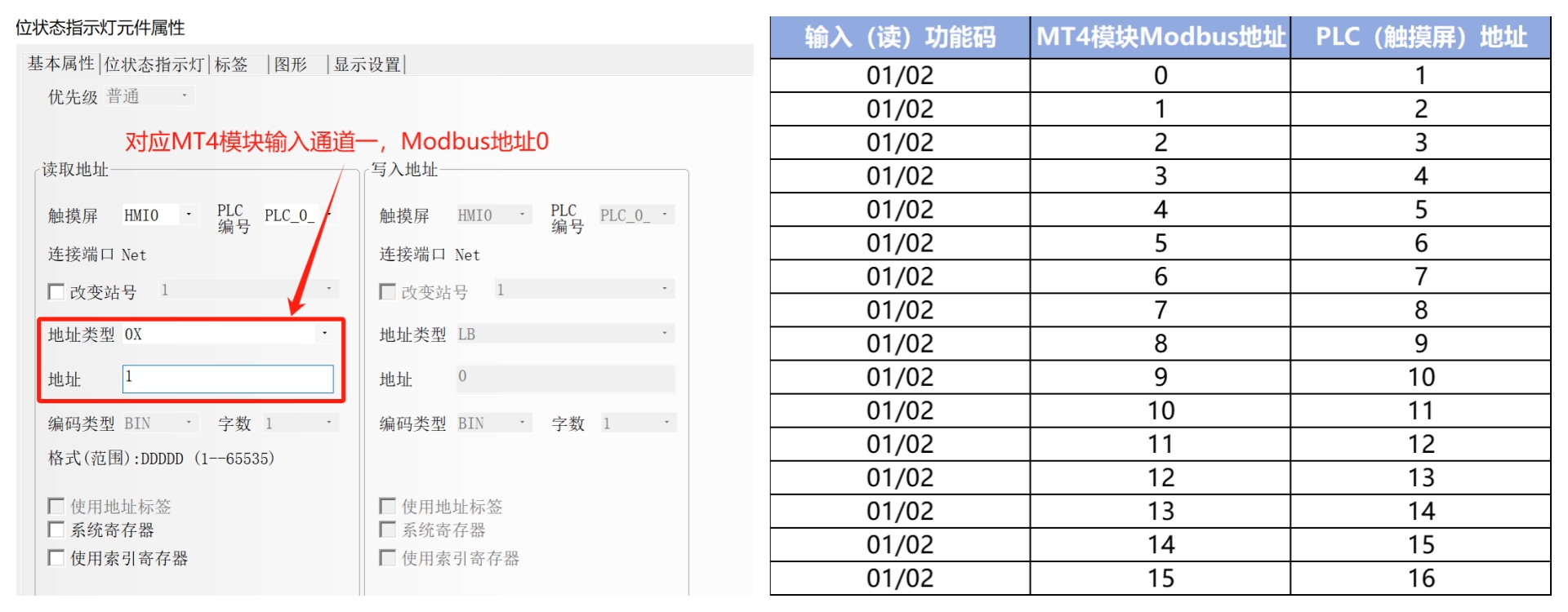

Read 16-bit DI Discrete Inputs: Function Codes 01/02, Modbus start address 0, length 16.

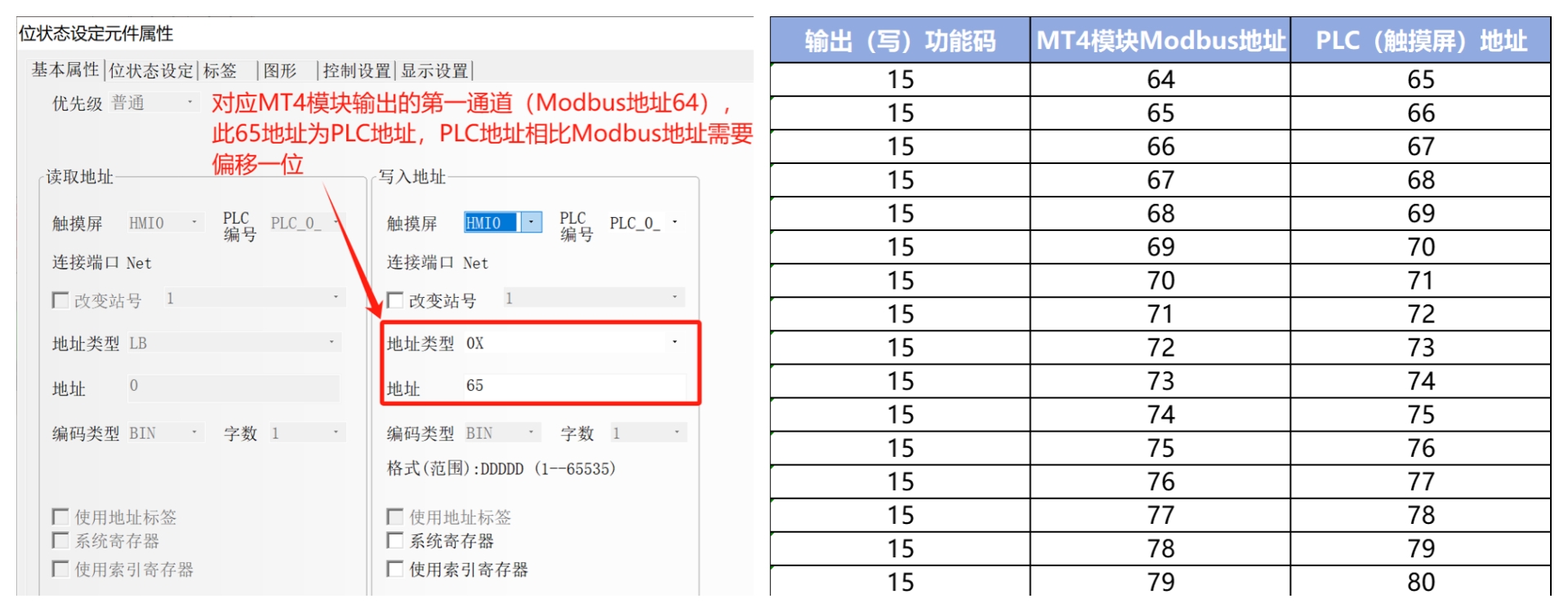

Write 16-bit DO Coil Outputs: Function Code 15, Modbus start address 64, length 16.

Implementation Steps:

Create bit-state toggle switches mapped to DO output addresses.

Create bit-state indicator lights mapped to DI input addresses.

This concludes the communication method between Solidot's Integrated I/O Modbus TCP Protocol Module and Kinco HMI. Thank you for reading!