Product Introduction: Solidot Remote I/O SSI Absolute Encoder Counting Module

The XB6S-PS20D is Solidot’s SSI absolute encoder counting module, compatible with the company’s remote I/O series couplers (XB6S series). The module supports industrial bus protocols such as EtherCAT, PROFINET, EtherNet/IP, and CC-Link IE Field Basic. It can interface with two 5V differential SSI absolute encoders, supports functions like counting and probe latching, and is suitable for industrial scenarios requiring position measurement and monitoring.

Key Features:

Supports dual-channel SSI encoder input with configurable frame length, LSB, and MSB.

Compatible with Gray code and binary code displays.

Bidirectional counting: Adapts flexibly to encoder rotation direction (forward/reverse).

Probe latching: Locks the current count value upon voltage change at the probe input pin.

1. Product Highlights

Multi-Channel Signal Processing Capability

Dual-Channel SSI Encoder Input

Supports two 5V differential SSI absolute encoders. Configurable data frame length (10–40 bits), maximum clock frequency of 2.0 MHz, and high real-time performance.Flexible Digital I/O

Input channels: 6 (4 probe latching inputs compatible with PNP/NPN; 2 general-purpose digital inputs).

Output channels: 8 NPN-type digital outputs with a maximum load current of 500 mA per channel.

High Precision and Configurability

Encoder Code Compatibility

Supports Gray code and binary code encoders.Probe Latching Function

Configurable for rising/falling edge triggers, single or continuous latching modes, with a response time ≤1 ms.

Industrial-Grade Reliability

Environmental Adaptability

Operating temperature: -20°C to +60°C; IP20 protection rating, suitable for industrial cabinet environments.Electrical Isolation

Opto-coupler isolation for input/output channels, isolation withstand voltage of 500V AC, and strong anti-interference capability.

2. Application Examples

Synchronous Control in Automotive Welding Production Lines

During body welding, the XB6S-PS20D connects two encoders to compare real-time position data between axes. It triggers output alarms when deviations exceed limits, ensuring welding alignment accuracy.

Positioning for Intelligent Warehouse Stackers

The XB6S-PS20D utilizes probe latching to record horizontal and vertical coordinates when a probe detects cargo arrival. Combined with PLC path planning, it ensures rapid and accurate cargo handling.

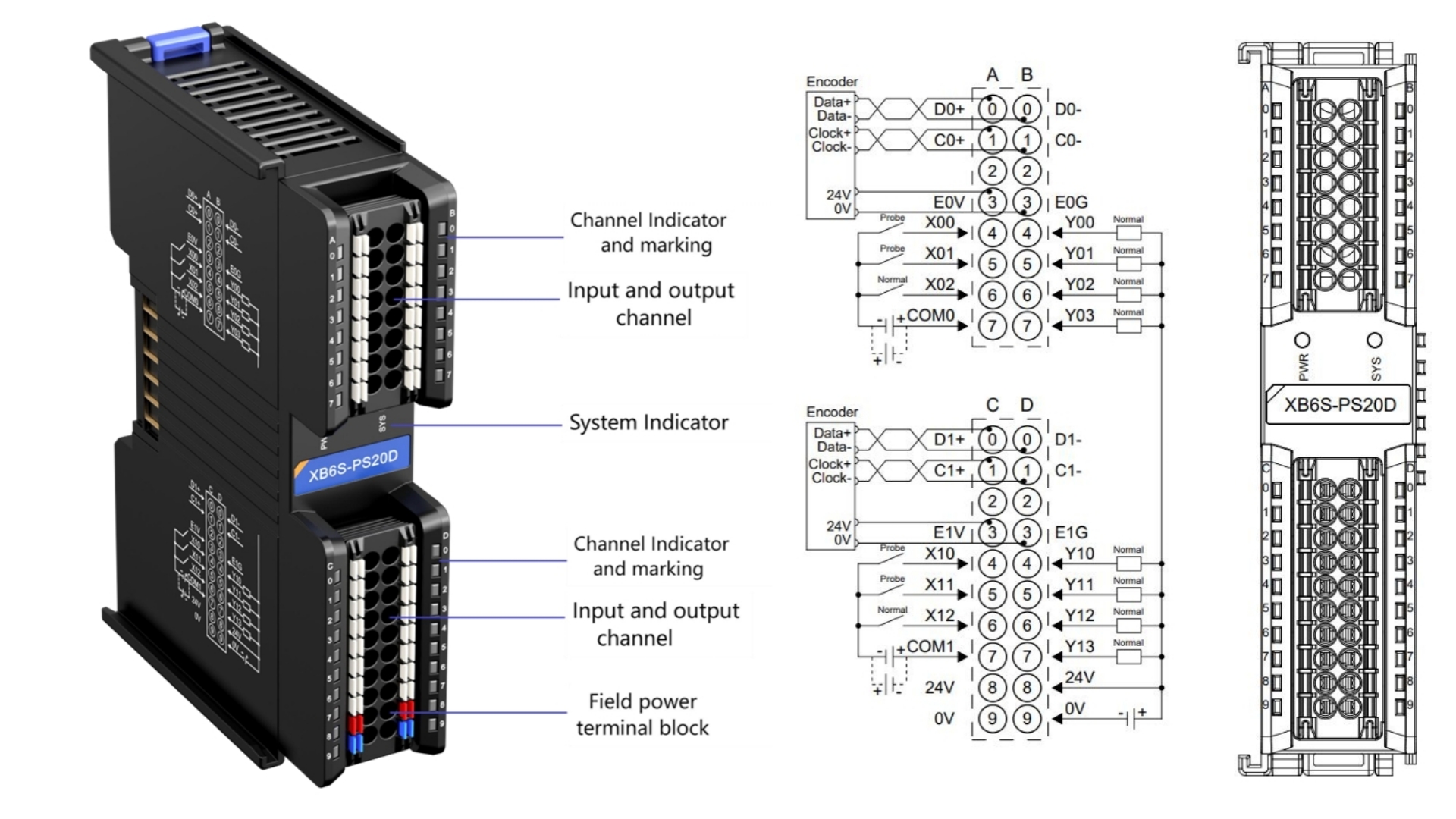

3. Panel Structure and Wiring Diagram

Left: XB6S-PS20D panel structure.

Right: XB6S-PS20D wiring diagram.

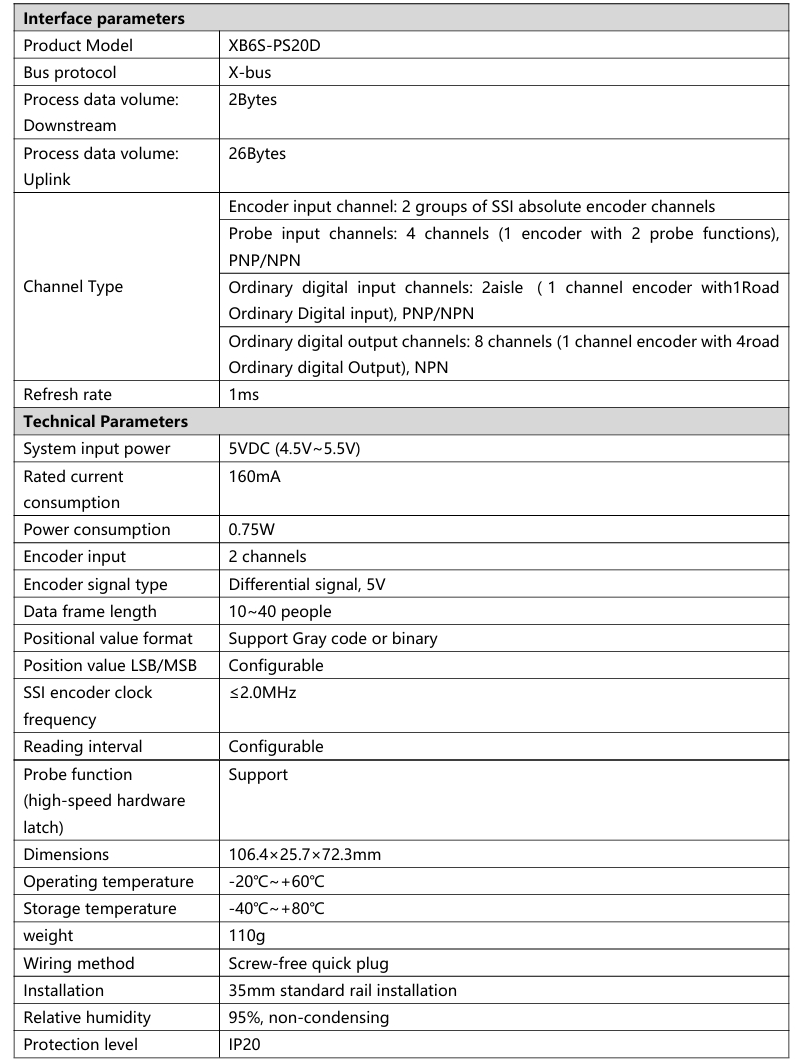

4. Technical Parameters

General Parameters

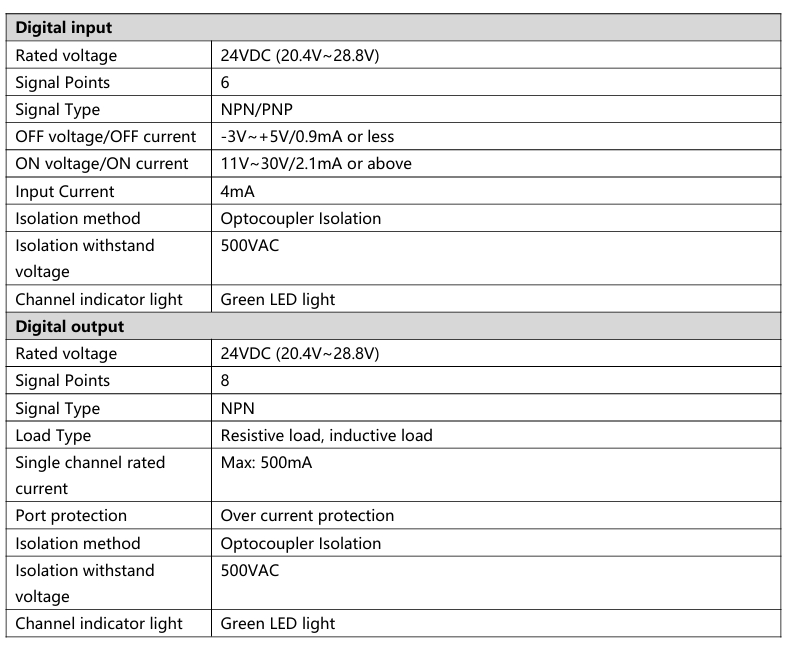

Digital I/O Parameters