Solidot All-in-One Serial Interface Gateway PN4-GW2FP: Pre-stored Multi-Command Sending Method

When using Solidot's all-in-one serial interface gateway PN4-GW2FP for PROFINET-to-freeport conversion, scenarios often require alternating multiple commands. The common method involves adding variable data to send different messages by modifying data at the same address. This Q&A introduces a second approach: using pre-stored multi-node messages to output distinct packets based on control words.

1. Configuration Process

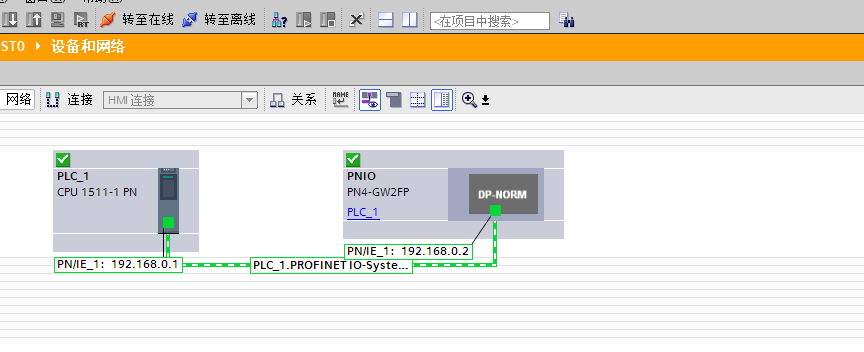

Add Siemens PLC series in TIA Portal and import PN4-GW2FP file.

Place the module in the network topology.

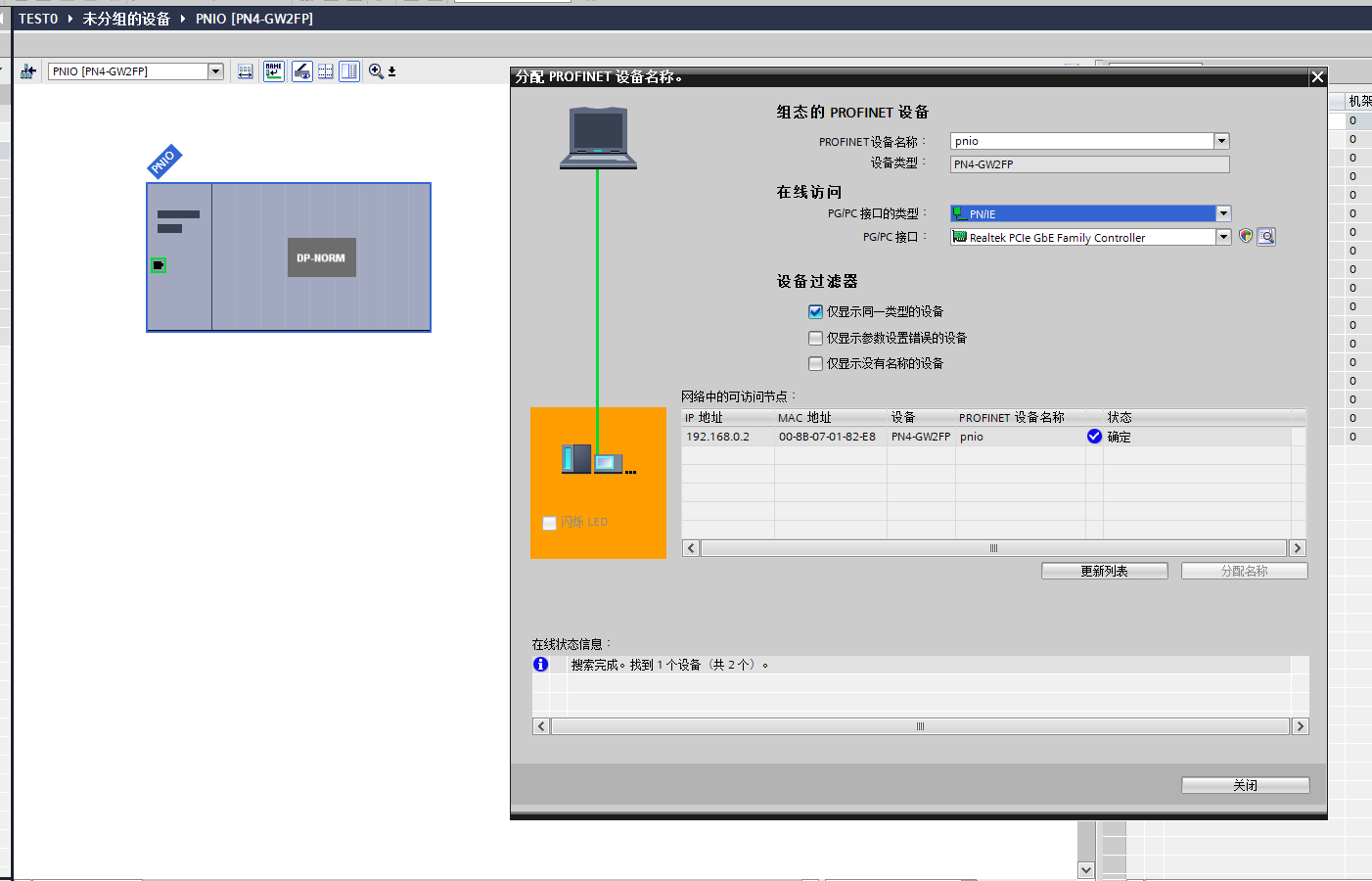

Connect PLC to PN4-GW2FP via Ethernet, assign device name and IP.

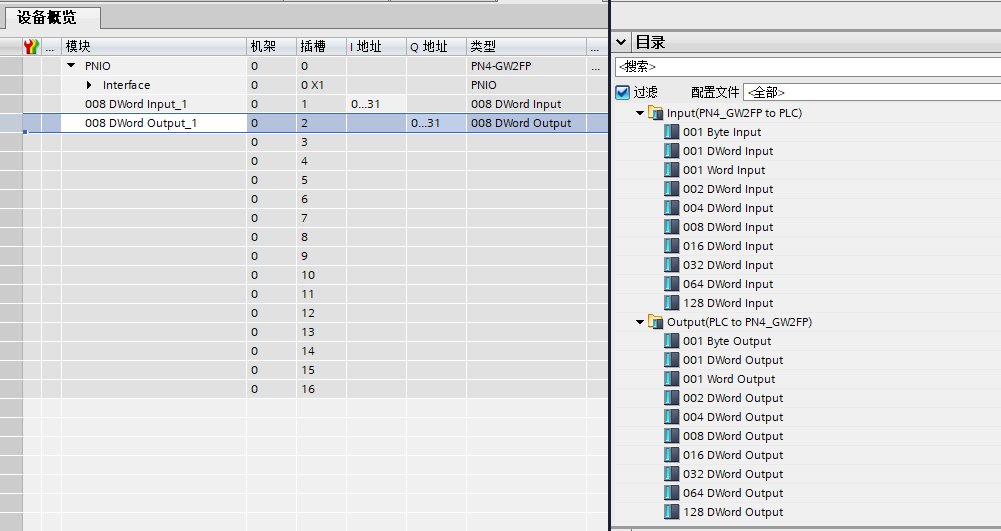

Configure input/output data areas in the module’s hardware settings.

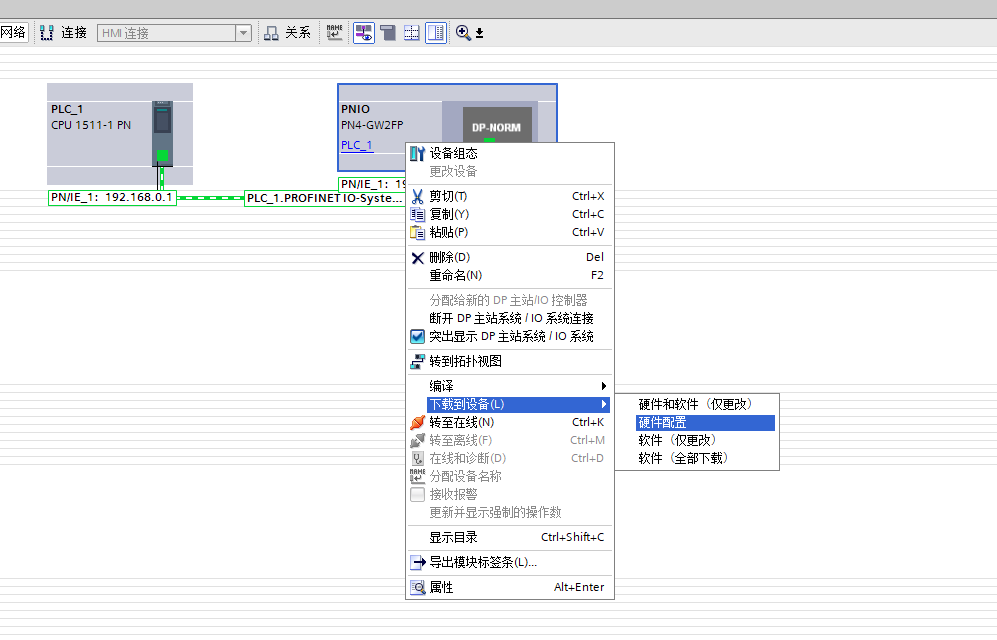

Right-click the module and select "Download Hardware Configuration".

2. Module Configuration

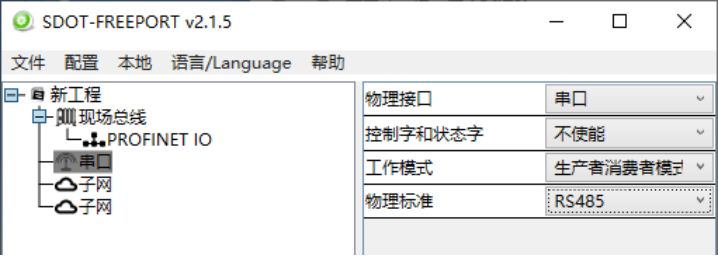

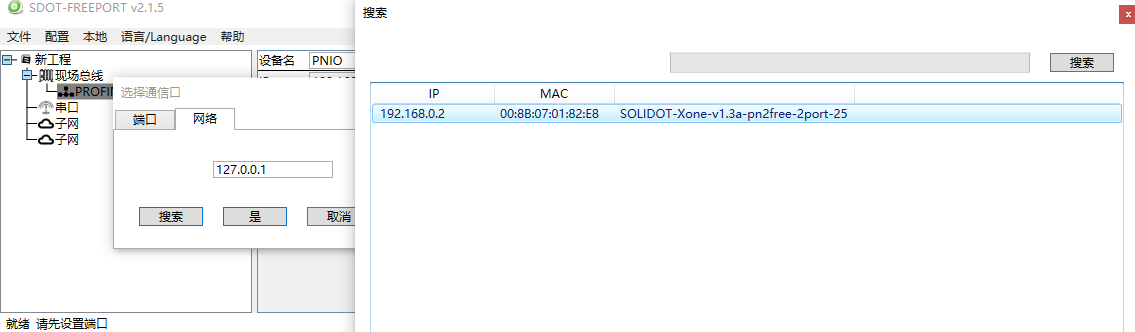

Open Solidot’s "SDOT-FREEPORT" software, create a project, select Producer-Consumer mode, and set physical interface (e.g., RS485).

Configure serial parameters: baud rate, data bits, parity, stop bits.

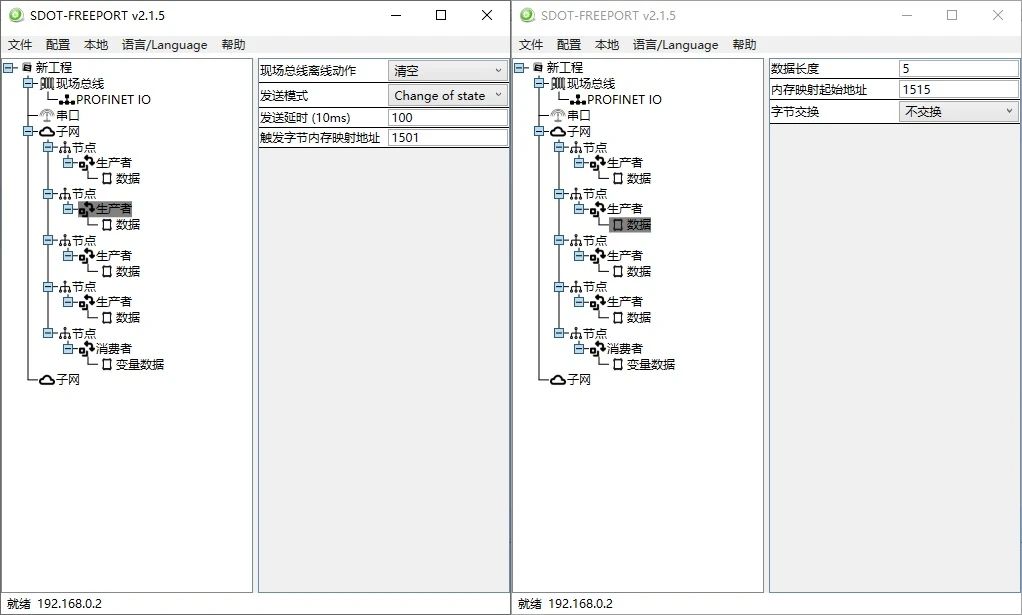

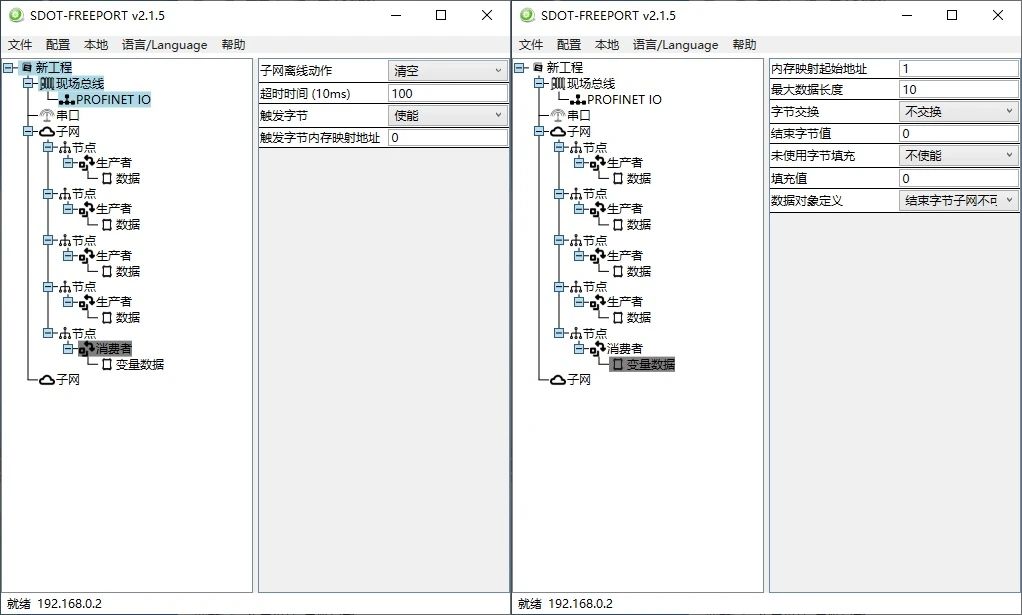

Add multiple nodes:

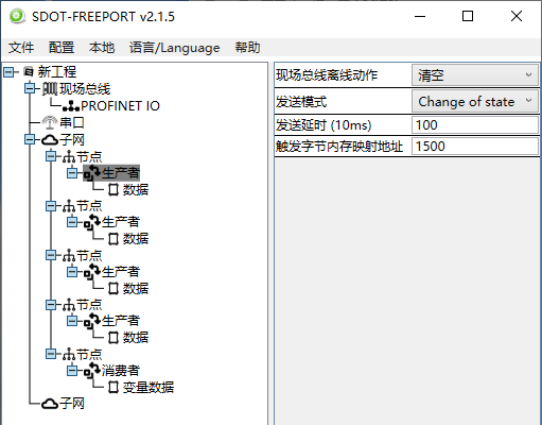

Node 1 Producer: Trigger on control word change (mapped to address 1500).

Add data area (length=5, mapped to address 1510).

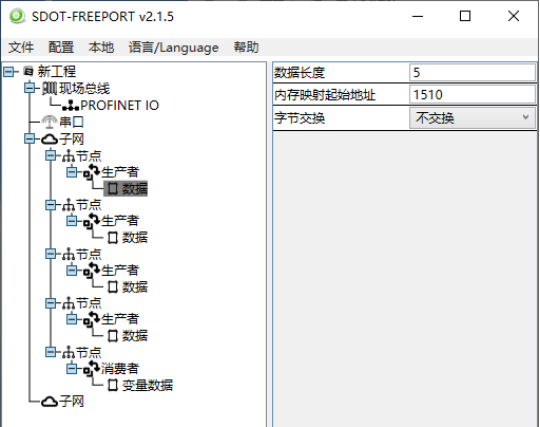

Node 2 Producer: Trigger address 1501, data area at 1515.

Consumer Node: Enable trigger byte=0, data length=10 bytes.

Download configuration to the module, restart PLC/module, and monitor online.

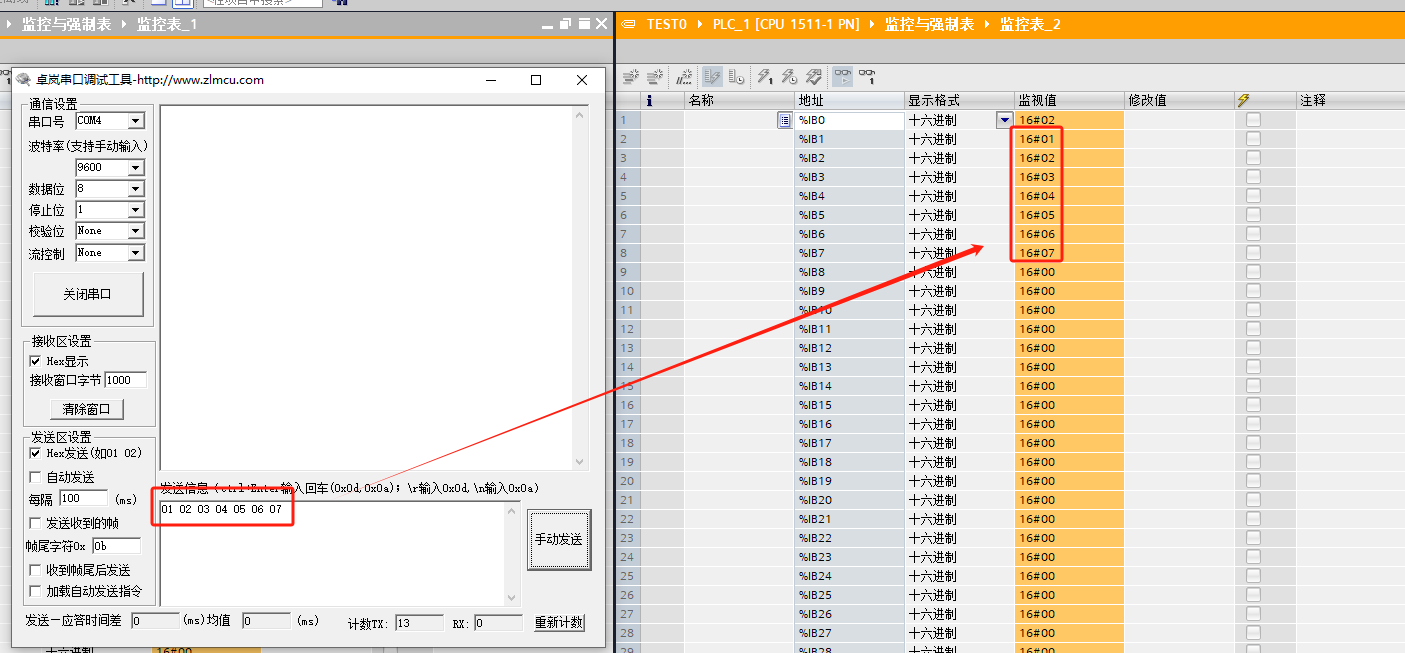

3. Data Monitoring

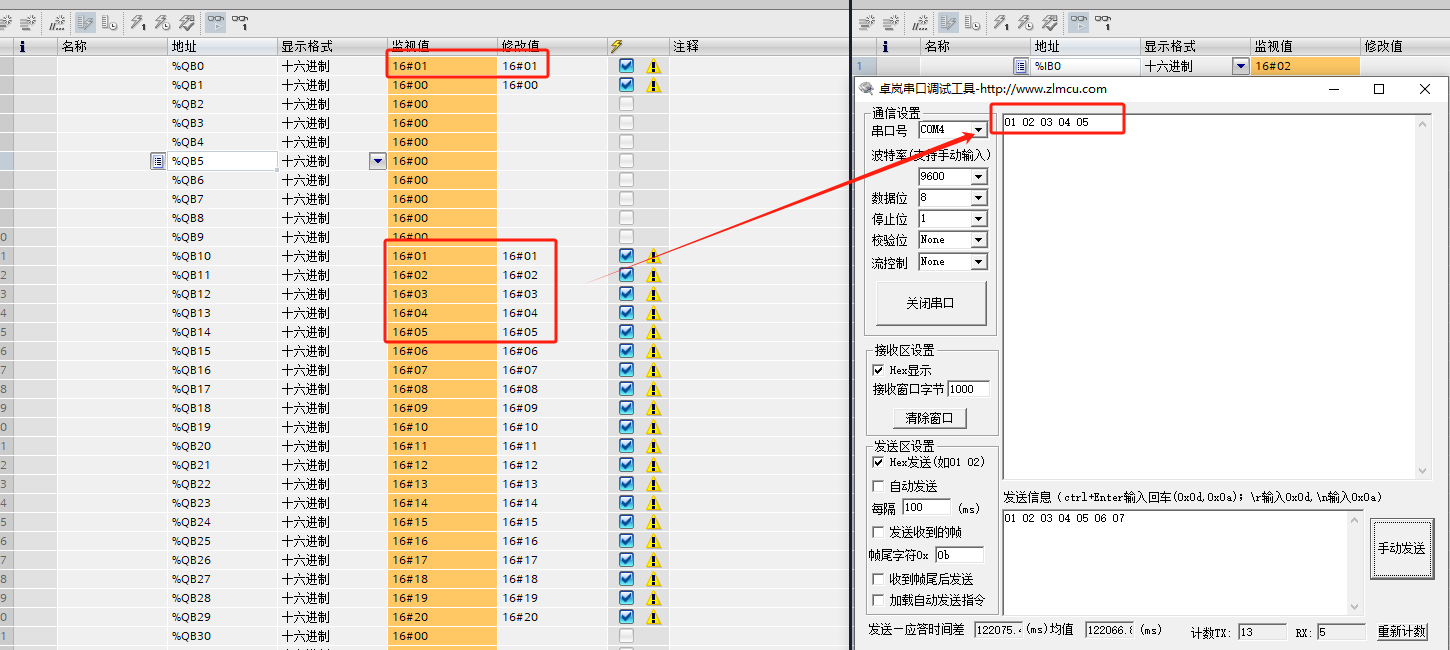

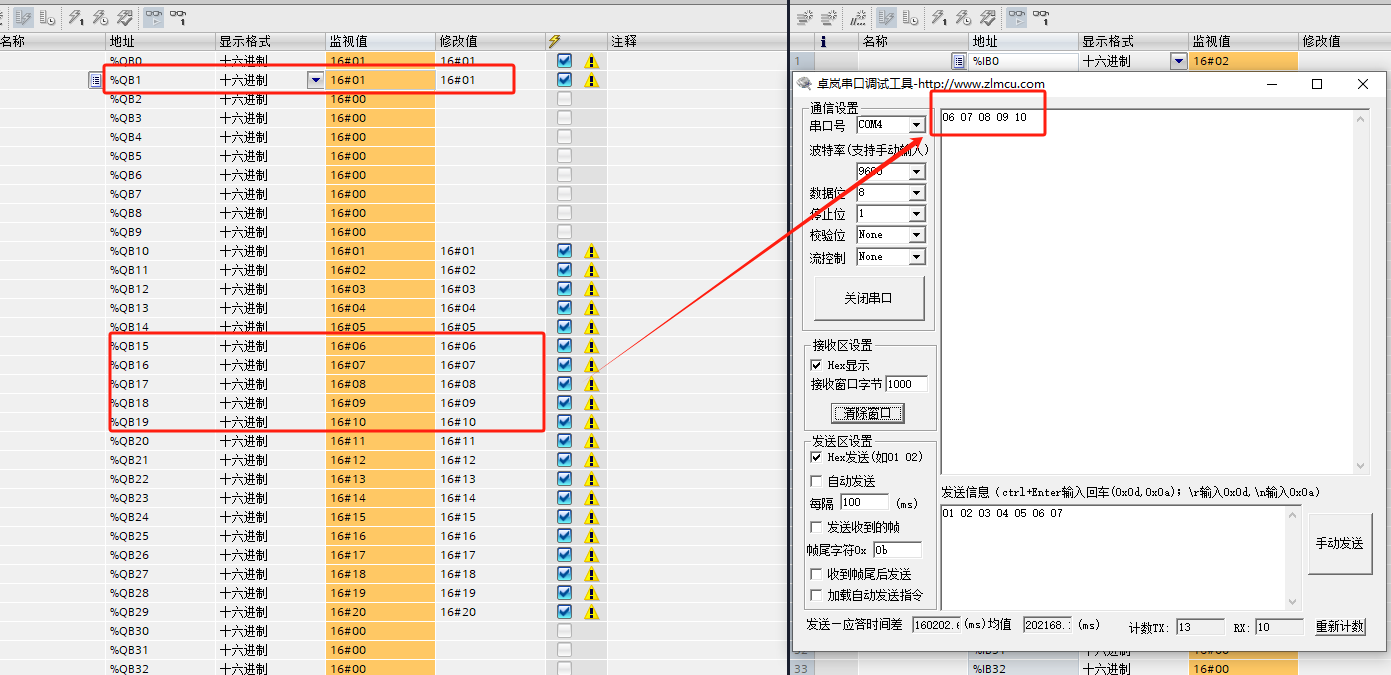

Preset data in QB10~QB29; trigger QB0/QB1 to send different messages.

Received data is mapped to TIA Portal’s address area.

Benefits: Reduces timing conflicts in multi-packet switching and enables pre-stored message sending without same-address limitations.

The above introduces the pre-stored multi-command sending method for Solidot's all-in-one serial interface gateway PN4-GW2FP. Should you have any inquiries, we welcome your questions and provide dedicated support.